Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT MASS AIR FLOW METER SUB-ASSEMBLY

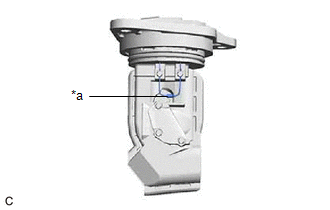

| (a) Perform a visual check for any foreign matter on the temperature sensor (thermistor) of the mass air flow meter sub-assembly shown in the illustration. OK: There is no foreign matter. If the result is not as specified, replace the mass air flow meter sub-assembly. |

|

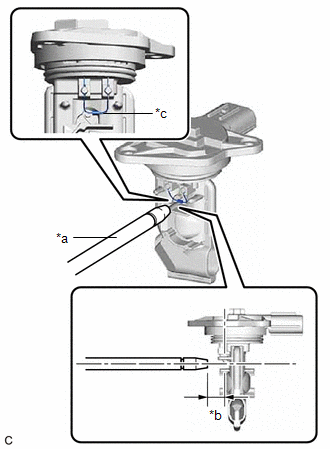

(b) Clean the intake air temperature sensor (thermistor).

NOTICE:

- Do not contact the mass air flow meter sub-assembly with the nozzle of the air blow gun.

- Do not insert the nozzle of the air blow gun into the intake air temperature sensor (thermistor) area.

|

*a | Air Blow Gun |

|

*b | 10 mm (0.394 in.) |

|

*c | Intake Air Temperature Sensor (Thermistor) |

| (1) Using an air blow gun, clean the intake air temperature sensor (thermistor) area of the mass air flow meter sub-assembly by applying approximately 10 intermittent bursts of air to the intake air temperature sensor (thermistor) area at a pressure of approximately 392 to 981 kPa (4.0 to 10.0 kgf/cm2, 57 to 142 psi). HINT: After performing cleaning, read the value of Data List item "MAF" using the GTS and if the value is not as specified, replace the mass air flow meter sub-assembly. |

|

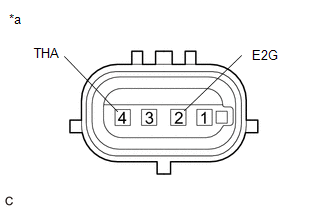

| (c) Check the intake air temperature sensor (thermistor) resistance. (1) Measure the resistance according to the value(s) in the table below. Standard Resistance:

If the result is not as specified, replace the mass air flow meter sub-assembly. |

|