Toyota Corolla Cross: Rear Wiper Motor Circuit

DESCRIPTION

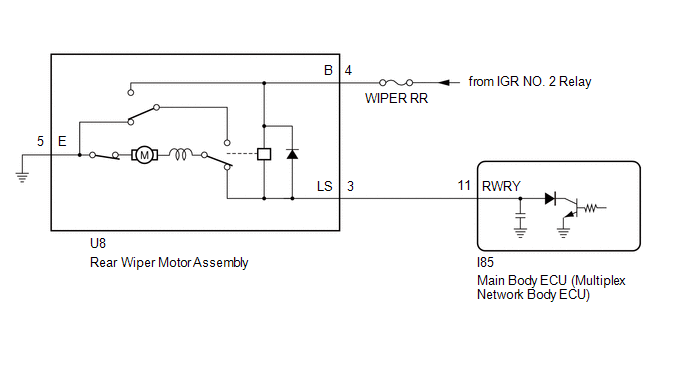

This circuit is the power source circuit for the rear wiper motor assembly.

WIRING DIAGRAM

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses of circuits related to this system before performing the following procedure.

- Before replacing the main body ECU (multiplex network body ECU), refer to Registration.*1

- for HEV Model:

Click here

.gif)

- for Gasoline Model:

Click here

.gif)

- *1: w/ Smart Key System

- for HEV Model:

PROCEDURE

|

1. | PERFORM ACTIVE TEST USING GTS (REAR WIPER OPERATION) |

(a) Perform the Active Test according to the display on the GTS.

Body Electrical > Main Body > Active Test|

Tester Display | Measurement Item |

Control Range | Diagnostic Note |

|---|---|---|---|

|

Rear Wiper Operation | Function to operate the rear wiper motor assembly |

OFF or ON | - |

|

Tester Display |

|---|

| Rear Wiper Operation |

OK:

Rear wiper motor assembly operates normally.

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

| 2. |

INSPECT REAR WIPER MOTOR ASSEMBLY |

Click here

.gif)

| NG | .gif) |

REPLACE REAR WIPER MOTOR ASSEMBLY |

|

| 3. |

CHECK HARNESS AND CONNECTOR (POWER SOURCE - REAR WIPER MOTOR ASSEMBLY) |

| (a) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 4. |

CHECK HARNESS AND CONNECTOR (REAR WIPER MOTOR ASSEMBLY - BODY GROUND) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U8-5 (E) - Body Ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 5. |

CHECK HARNESS AND CONNECTOR (REAR WIPER MOTOR ASSEMBLY - MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU)) |

(a) Disconnect the I85 main body ECU (multiplex network body ECU) connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

U8-3 (LS) - I85-11 (RWRY) |

Always | Below 1 Ω |

|

U8-3 (LS) or I85-11 (RWRY) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR |

.gif)