Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

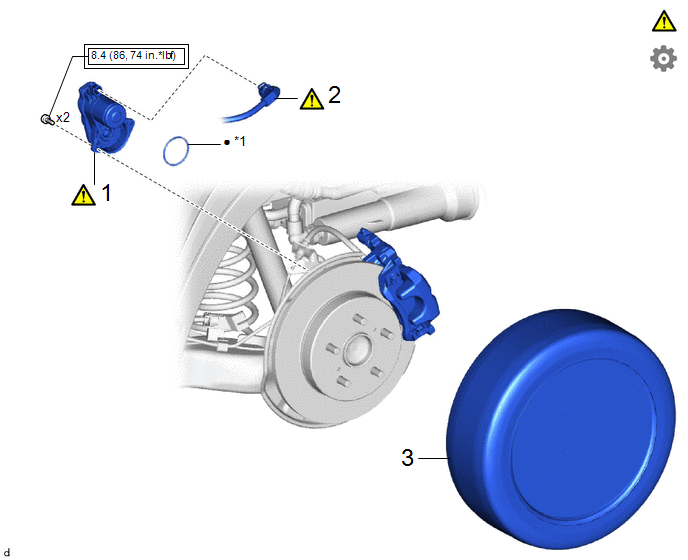

1 |

PARKING BRAKE ACTUATOR ASSEMBLY |

46310B |

|

- |

- |

|

2 |

NO. 2 PARKING BRAKE WIRE ASSEMBLY |

890C0A |

|

- |

- |

|

3 |

REAR WHEEL |

- |

- |

- |

- |

|

*1 |

O-ring |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

● |

Non-reusable part |

.png) |

Lithium soap base glycol grease |

- |

- |

CAUTION / NOTICE / HINT

HINT:

- Use the same procedure for the RH side and LH side.

- The following procedure is for the LH side.

PROCEDURE

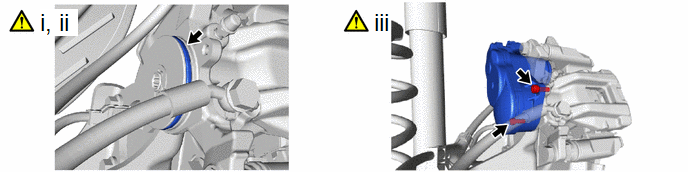

1. INSTALL PARKING BRAKE ACTUATOR ASSEMBLY

(1) Apply a light coat of lithium soap base glycol grease to a new O-ring.

(2) Install the O-ring to the rear disc brake cylinder assembly.

NOTICE:

Make sure to replace the O-ring with a new one when installing the parking brake actuator assembly.

(3) Using a 5 mm hexagon socket wrench, install the parking brake actuator assembly to the rear disc brake cylinder assembly with the 2 bolts.

Torque:

8.4 N·m {86 kgf·cm, 74 in·lbf}

2. CONNECT NO. 2 PARKING BRAKE WIRE ASSEMBLY

.png) |

NOTICE:

|

3. INSTALL REAR WHEEL

Click here .gif)