Toyota Corolla Cross: Disassembly

DISASSEMBLY

CAUTION / NOTICE / HINT

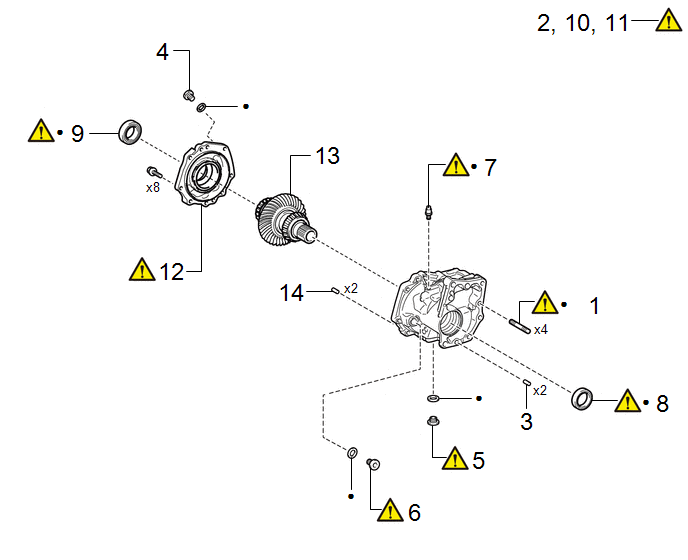

COMPONENTS (DISASSEMBLY)

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

1 |

TRANSFER AND TRANSAXLE SETTING STUD BOLT |

36100A |

|

- |

- |

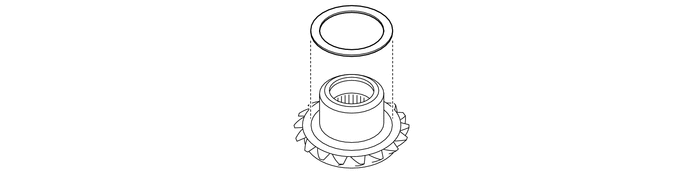

|

2 |

SECURE TRANSFER ASSEMBLY |

36100 |

|

- |

- |

|

3 |

TRANSFER CASE STRAIGHT PIN |

36111G |

- |

- |

- |

|

4 |

NO. 1 TRANSFER CASE PLUG |

36114B |

- |

- |

- |

|

5 |

TRANSFER DRAIN PLUG |

36114F |

|

- |

- |

|

6 |

TRANSFER FILLER PLUG |

36114L |

|

- |

- |

|

7 |

TRANSFER CASE BREATHER PLUG |

36111H |

|

- |

- |

|

8 |

TRANSFER CASE OIL SEAL |

36111B |

|

- |

- |

|

9 |

TRANSFER CASE OIL SEAL RH |

36113D |

|

- |

- |

|

10 |

INSPECT TOTAL PRELOAD |

- |

|

- |

- |

|

11 |

INSPECT RING GEAR BACKLASH |

- |

|

- |

- |

|

12 |

NO. 1 TRANSFER CASE COVER |

36121 |

|

- |

- |

|

13 |

TRANSFER RING GEAR |

- |

- |

- |

- |

|

14 |

TRANSFER CASE STRAIGHT PIN |

36111G |

- |

- |

- |

|

● |

Non-reusable part |

★ |

Precoated part |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

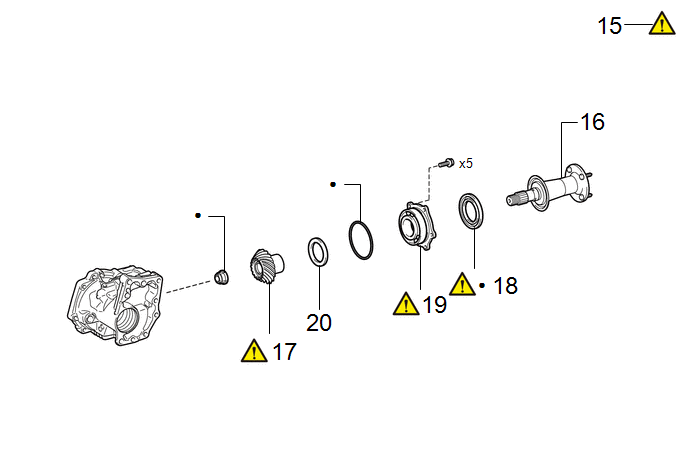

15 |

INSPECT DRIVEN PINION PRELOAD |

- |

|

- |

- |

|

16 |

REAR TRANSFER OUTPUT SHAFT SUB-ASSEMBLY |

36202 |

- |

- |

- |

|

17 |

TRANSFER DRIVEN PINION |

- |

|

- |

- |

|

18 |

REAR TRANSFER OUTPUT SHAFT DUST DEFLECTOR |

33325A |

|

- |

- |

|

19 |

TRANSFER BEARING ASSEMBLY |

36250 |

|

- |

- |

|

20 |

TRANSFER OUTPUT SHAFT WASHER |

36275E |

- |

- |

- |

|

● |

Non-reusable part |

- |

- |

|

Procedure |

Part Name Code |

.png) |

.png) |

.png) |

|

|---|---|---|---|---|---|

|

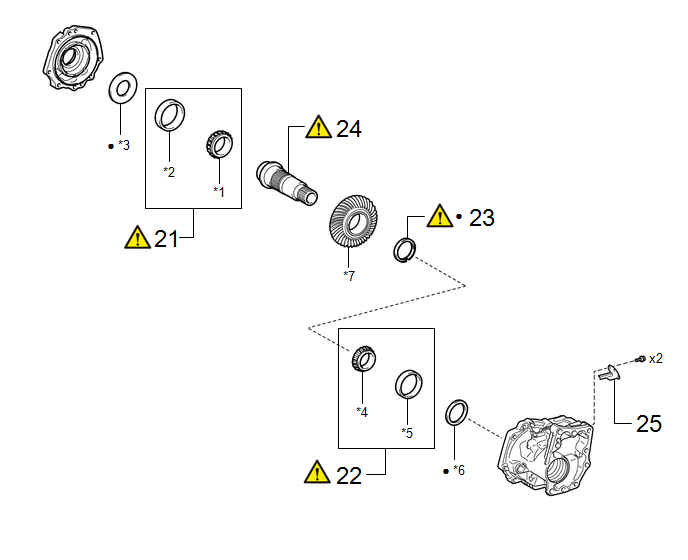

21 |

RING GEAR MOUNTING CASE BEARING RH |

41301H |

|

- |

- |

|

22 |

RING GEAR MOUNTING CASE BEARING LH |

41301H |

|

- |

- |

|

23 |

SHAFT SNAP RING |

36212L |

|

- |

- |

|

24 |

TRANSFER RING GEAR MOUNTING CASE |

41319 |

|

- |

- |

|

25 |

BREATHER OIL DEFLECTOR |

36128B |

- |

- |

- |

|

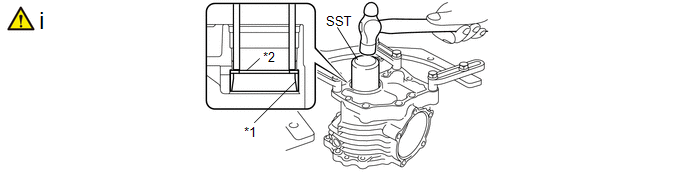

*1 |

RING GEAR MOUNTING CASE BEARING RH (INNER RACE) |

*2 |

RING GEAR MOUNTING CASE BEARING RH (OUTER RACE) |

|

*3 |

NO. 2 TRANSFER RING GEAR MOUNTING CASE WASHER |

*4 |

RING GEAR MOUNTING CASE BEARING LH (INNER RACE) |

|

*5 |

RING GEAR MOUNTING CASE BEARING LH (OUTER RACE) |

*6 |

NO. 1 RING GEAR MOUNTING CASE WASHER |

|

*7 |

TRANSFER RING GEAR |

- |

- |

|

● |

Non-reusable part |

- |

- |

CAUTION / NOTICE / HINT

NOTICE:

Before installation of each part, thoroughly clean and dry it. Then apply grease or oil as necessary. Do not use alkaline chemicals to clean aluminum parts, rubber parts or precoated bolts. Also, do not use non-residue solvent or other cleaning oils to clean O-rings, oil seals or rubber parts.

PROCEDURE

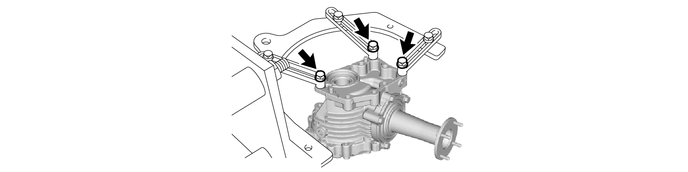

1. REMOVE TRANSFER AND TRANSAXLE SETTING STUD BOLT

(1) Using 2 nuts, remove the 4 transfer and transaxle setting stud bolts.

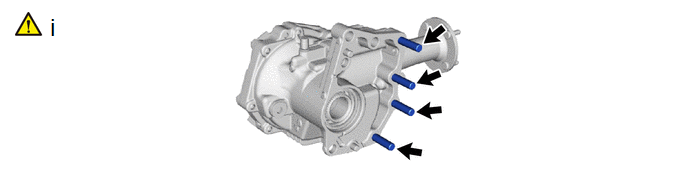

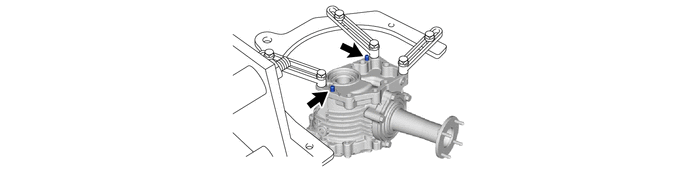

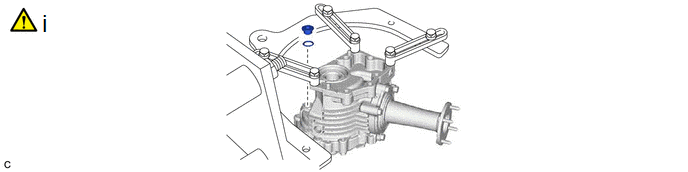

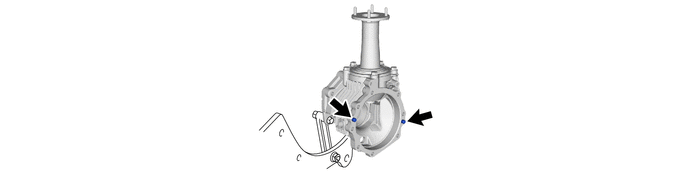

2. SECURE TRANSFER ASSEMBLY

3. REMOVE TRANSFER CASE STRAIGHT PIN

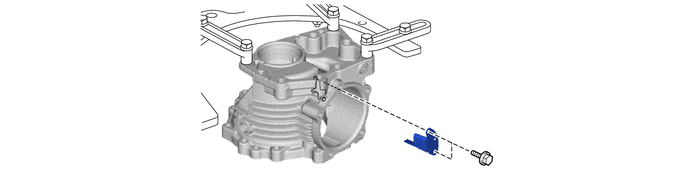

4. REMOVE NO. 1 TRANSFER CASE PLUG

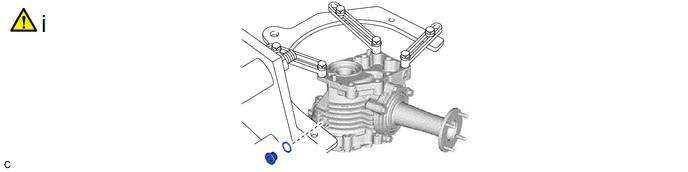

5. REMOVE TRANSFER DRAIN PLUG

(1) Using a 10 mm socket hexagon wrench, remove the transfer drain plug and gasket.

6. REMOVE TRANSFER FILLER PLUG

(1) Using a 10 mm socket hexagon wrench, remove the transfer filler plug and gasket.

7. REMOVE TRANSFER CASE BREATHER PLUG

(1) Using a chisel and hammer, slightly pry out the transfer case breather plug.

(2) Using a screwdriver, lightly pry up and remove the transfer case breather plug.

8. REMOVE TRANSFER CASE OIL SEAL

.png) |

Click here |

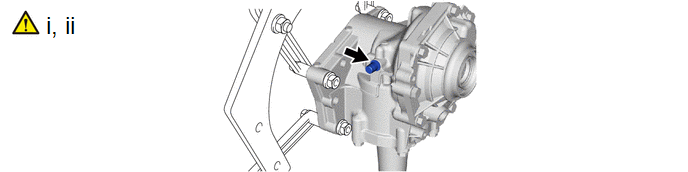

9. REMOVE TRANSFER CASE OIL SEAL RH

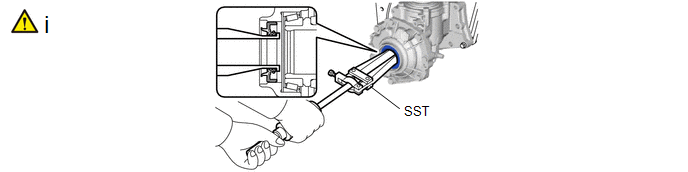

(1) Using SST, remove the transfer case oil seal RH from the No. 1 transfer case cover.

SST: 09308-00010

NOTICE:

Do not scratch the press-fitting surface of the transfer case oil seal RH.

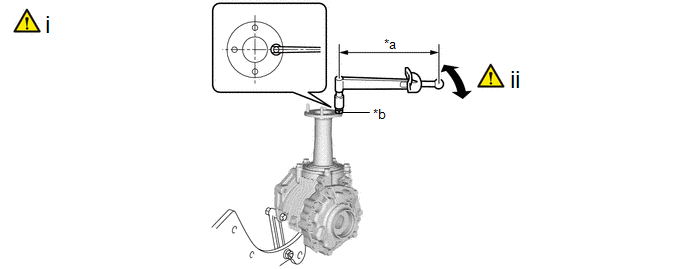

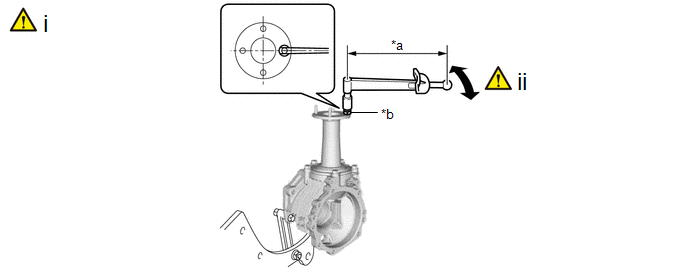

10. INSPECT TOTAL PRELOAD

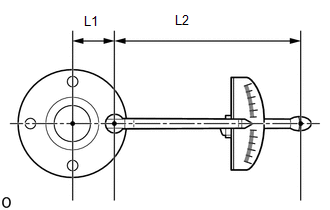

|

*a |

Torque Wrench Fulcrum Length |

*b |

Double Nut |

(1) Install the double nut to the transfer output shaft stud bolt and set the torque wrench into place.

HINT:

Adjust the double nut until the torque wrench is straight.

(2) Using a torque wrench, measure the total preload (starting torque) with the teeth of the drive pinion and ring gear in contact.

Standard preload (at starting):

0.87 to 2.85 N*m (8.88 to 29.06 kgf*cm, 7.71 to 25.22 in.*lbf)

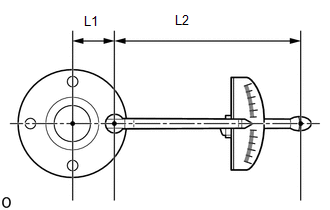

HINT:

- When using a torque wrench after changing its effective length, determine

the reading of the torque wrench.

Formula T'=T x L2/(L1+L2)

Formula T'=T x L2/(L1+L2)

T'

Reading of torque wrench (N*m (kgf*cm, ft.*lbf))

T

Driven pinion preload (N*m (kgf*cm, ft.*lbf))

L1

Distance from center of transfer output shaft to center of stud bolt (cm (in.))

L2

Length of torque wrench (cm (in.))

- Distance from center of transfer output shaft to center of stud bolt (effective length of 33.9 mm) when using a torque wrench (effective length of 160 mm): 0.70 to 2.29 N*m (7.14 to 23.35 kgf*cm, 6.20 to 20.26 in.*lbf)

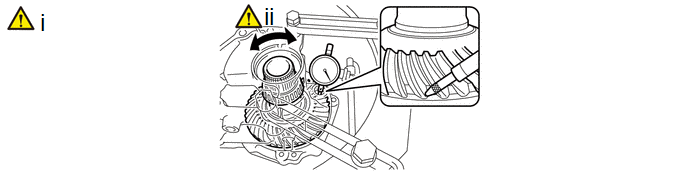

11. INSPECT RING GEAR BACKLASH

(1) Insert a dial indicator through the No. 2 transfer case plug hole, and set it perpendicular to the edge of a ring gear tooth.

If the backlash is not within the specified range, adjust the backlash or repair as necessary.

(2) While securing the transfer output shaft by hand, rotate the transfer ring gear mounting case forward and backward by hand and measure the backlash of the ring gear and driven pinion.

Standard backlash:

0.10 to 0.20 mm (0.00394 to 0.00787 in.)

NOTICE:

Measure the ring gear at 3 or more locations.

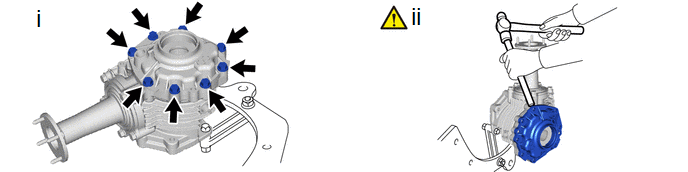

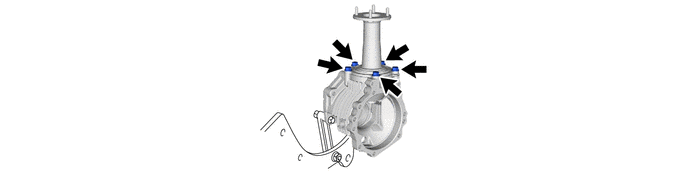

12. REMOVE NO. 1 TRANSFER CASE COVER

(1) Remove the 8 bolts.

(2) Using a brass bar and hammer, remove the No. 1 transfer case cover from the transfer case.

NOTICE:

- Put the brass bar against the rib of the No. 1 transfer case cover.

- When removing the No. 1 transfer case cover, be careful not to scratch the installation surface.

HINT:

To prevent the No. 1 transfer case cover from falling, leave 2 of the bolts screwed in by 5 or 6 threads.

13. REMOVE TRANSFER RING GEAR

14. REMOVE TRANSFER CASE STRAIGHT PIN

15. INSPECT DRIVEN PINION PRELOAD

|

*a |

Torque Wrench Fulcrum Length |

*b |

Double Nut |

(1) Install the double nut to the transfer output shaft stud bolt and set the torque wrench into place.

HINT:

Adjust the double nut until the torque wrench is straight.

(2) Using a torque wrench, measure the preload (starting torque) of the drive pinion.

Standard preload (at starting):

0.39 to 2.21 N*m (3.98 to 22.53 kgf*cm, 3.46 to 19.55 in.*lbf)

HINT:

- When using a torque wrench after changing its effective length, determine

the reading of the torque wrench.

Formula T'=T x L2/(L1+L2)

Formula T'=T x L2/(L1+L2)

T'

Reading of torque wrench (N*m (kgf*cm, ft.*lbf))

T

Driven pinion preload (N*m (kgf*cm, ft.*lbf))

L1

Distance from center of transfer output shaft to center of stud bolt (cm (in.))

L2

Length of torque wrench (cm (in.))

- Distance from center of transfer output shaft to center of stud bolt (effective length of 33.9 mm) when using a torque wrench (effective length of 160 mm): 0.32 to 1.77 N*m (3.27 to 18.04 kgf*cm, 2.84 to 15.66 in.*lbf)

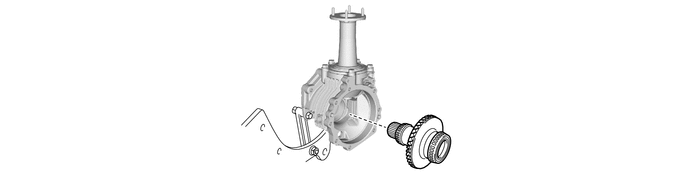

16. REMOVE REAR TRANSFER OUTPUT SHAFT SUB-ASSEMBLY

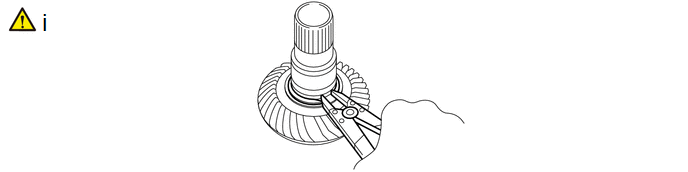

17. REMOVE TRANSFER DRIVEN PINION

(1) Mount the rear transfer output shaft sub-assembly in a vise between aluminum plates.

NOTICE:

Do not overtighten the vise.

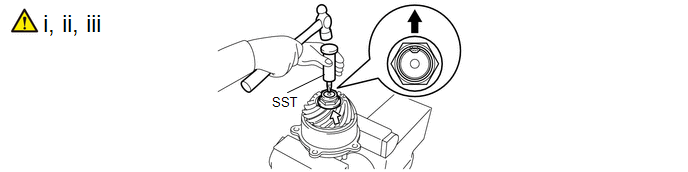

(2) Using SST and a hammer, unstake the transfer gear nut.

SST: 09930-00010

NOTICE:

- Be sure to use SST with the tapered surface facing the shaft.

- Do not grind the tip of SST with a grinder or other device.

- Completely loosen the staked part of the transfer gear nut when removing it.

- Do not damage the threads of the output shaft sub-assembly.

(3) Using a 30 mm socket wrench, remove the transfer gear nut.

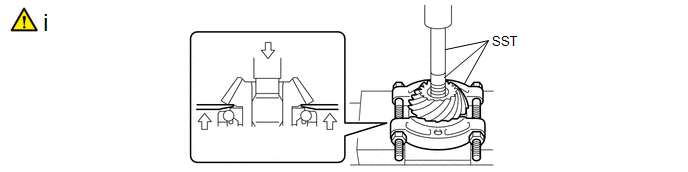

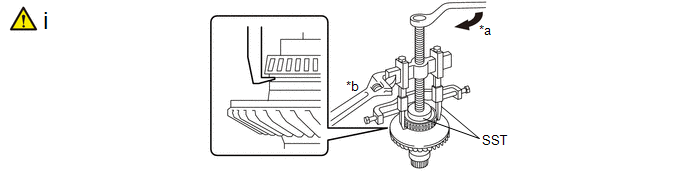

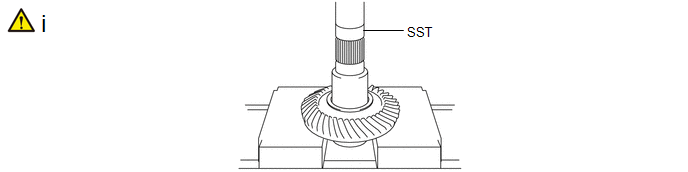

(1) Using SST and a press, remove the transfer driven pinion from the rear transfer output shaft sub-assembly.

SST: 09950-00020

SST: 09950-60011

09951-00240

SST: 09950-70010

09951-07100

NOTICE:

Support the front transfer driven pinion bearing as shown in the illustration to avoid placing stress on the outer race.

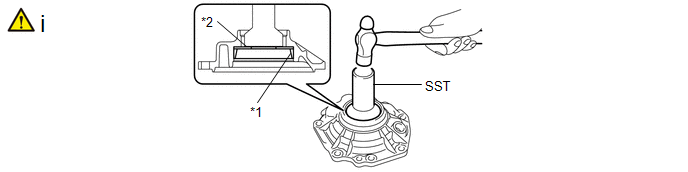

18. REMOVE REAR TRANSFER OUTPUT SHAFT DUST DEFLECTOR

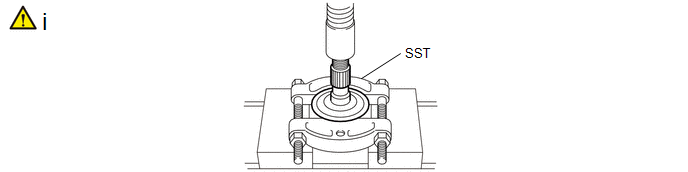

(1) Using SST and a press, remove the rear transfer output shaft dust deflector from the rear transfer output shaft sub-assembly.

SST: 09950-00020

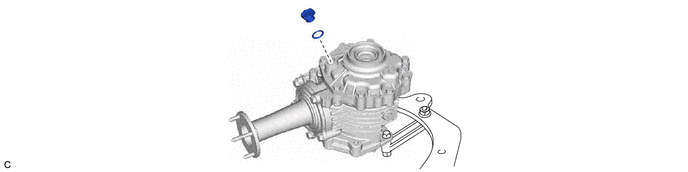

19. REMOVE TRANSFER BEARING ASSEMBLY

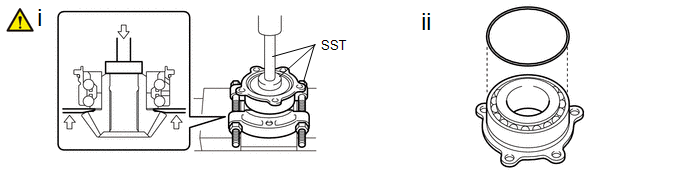

(1) Using SST and a press, remove the front transfer driven pinion bearing from the transfer driven pinion.

SST: 09950-00020

SST: 09950-60011

09951-00410

SST: 09950-70010

09951-07100

NOTICE:

Support the front transfer driven pinion bearing as shown in the illustration to avoid placing stress on the outer race.

(2) Remove the O-ring from the front transfer driven pinion bearing.

20. REMOVE TRANSFER OUTPUT SHAFT WASHER

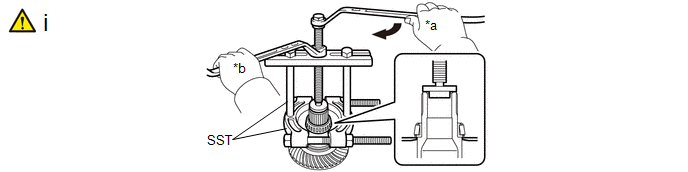

21. REMOVE RING GEAR MOUNTING CASE BEARING RH

|

*a |

Turn |

*b |

Hold |

(1) Using SST, remove the ring gear mounting case bearing RH (inner race) from the transfer ring gear mounting case.

SST: 09950-40011

09951-04010

09952-04010

09953-04030

09954-04010

09955-04061

09957-04010

09958-04011

SST: 09950-60011

09951-00540

NOTICE:

- Apply a lubricant to the threads and end of SST.

- Do not deform the cage of the ring gear mounting case bearing RH (inner race) (when reusing the bearing).

- Place identification marks on the left and right ring gear mounting case bearings to distinguish them (backside, teeth side). Then store them separately (when reusing the bearings).

|

*1 |

Ring Gear Mounting Case Bearing RH (Outer Race) |

*2 |

No. 2 Transfer Ring Gear Mounting Case Washer |

(1) Using SST and a hammer, remove the No. 2 transfer ring gear mounting case washer and ring gear mounting case bearing RH (outer race) from the No. 1 transfer case cover.

SST: 09310-35010

22. REMOVE RING GEAR MOUNTING CASE BEARING LH

|

*a |

Turn |

*b |

Hold |

(1) Using SST, remove the ring gear mounting case bearing LH (inner race) from the transfer ring gear mounting case.

SST: 09950-00020

SST: 09950-00030

NOTICE:

- Apply a lubricant to the threads and end of SST.

- Do not deform the cage of the ring gear mounting case bearing LH (inner race) (when reusing the bearing).

- Place identification marks on the left and right ring gear mounting case bearings to distinguish them (backside, teeth side). Then store them separately (when reusing the bearings).

|

*1 |

Ring Gear Mounting Case Bearing LH (Outer Race) |

*2 |

No. 1 Ring Gear Mounting Case Washer |

(1) Using SST and a hammer, remove the No. 1 ring gear mounting case washer and ring gear mounting case bearing LH (outer race) from the transfer case.

SST: 09636-20010

23. REMOVE SHAFT SNAP RING

(1) Using a snap ring expander, remove the shaft snap ring.

24. REMOVE TRANSFER RING GEAR MOUNTING CASE

(1) Using SST and a press, remove the transfer ring gear mounting case from the transfer ring gear.

SST: 09950-60011

09951-00400

25. REMOVE BREATHER OIL DEFLECTOR

.gif)