Toyota Corolla Cross: Cooling Fan Circuit

DESCRIPTION

The ECM turns on or off the fan relays using signals calculated from the engine coolant temperature, air conditioning switch (on/off), air conditioning refrigerant pressure, engine speed and vehicle speed signals.

The ECM switches the circuit of the cooling fan motors between series and parallel by turning on or off the fan relays in order to control the speed of the cooling fan motors in two steps.

WIRING DIAGRAM

.png)

CAUTION / NOTICE / HINT

NOTICE:

- Inspect the fuses for circuits related to this system before performing the following procedure.

- Before replacing the ECM, refer to Service Bulletin.

PROCEDURE

|

1. | PERFORM ACTIVE TEST USING GTS (CONTROL THE ENGINE COOLING FAN) |

(a) Connect the GTS to the DLC3.

(b) Turn the ignition switch to ON (IG)

(c) Turn the GTS on.

(d) Enter the following menus: Powertrain / Engine / Active Test / Control the Engine Cooling Fan.

Powertrain > Engine > Active Test|

Tester Display |

|---|

| Control the Engine Cooling Fan |

(e) Perform the Active Test according to the display on the GTS.

OK:

|

Active Tester Operation | Fan Operation |

|---|---|

|

HIGH | Cooling fans high speed operate |

|

LOW | Cooling fans low speed operate |

|

OFF | Cooling fans stop |

| OK | .gif) | PROCEED TO NEXT SUSPECTED AREA SHOWN IN PROBLEM SYMPTOMS TABLE |

|

| 2. |

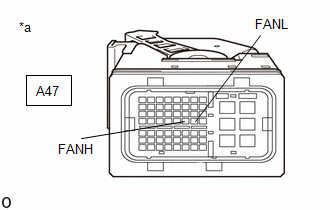

CHECK HARNESS AND CONNECTOR (FANL - FANH POWER SOURCE) |

(a) Disconnect the A47 ECM connector.

(b) Turn the ignition switch to ON (IG)

| (c) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

| NG | .gif) | GO TO STEP 12 |

|

| 3. |

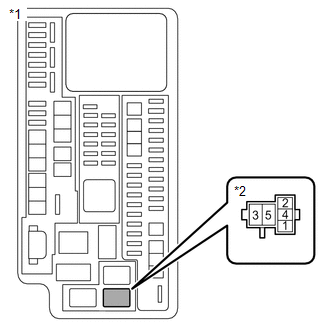

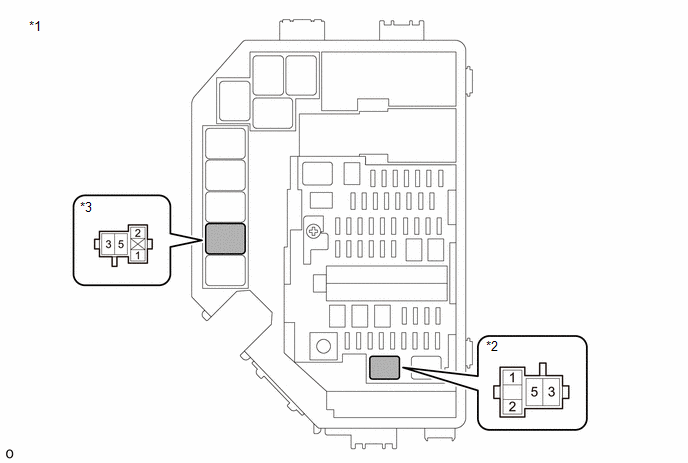

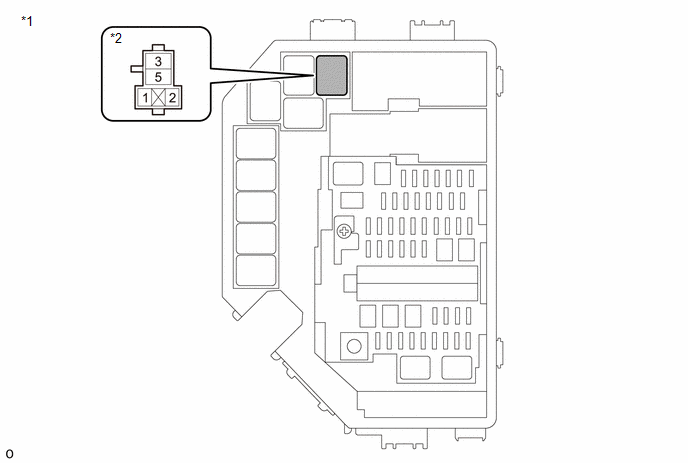

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY AND FAN NO. 3 RELAY POWER SOURCE CIRCUIT) |

(a) Remove the FAN NO. 1 relay from the No. 2 relay block.

(b) Remove the FAN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the voltage according to the value(s) in the table below.

|

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | FAN NO. 1 Relay |

|

*3 | FAN NO. 3 Relay |

- | - |

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

3 (FAN NO. 1 relay) - Body ground |

Always | 11 to 14 V |

|

3 (FAN NO. 3 relay) - Body ground |

Always | 11 to 14 V |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY AND FAN NO. 3 RELAY POWER SOURCE CIRCUIT) |

|

| 4. |

INSPECT COOLING FAN RELAY (FAN NO. 1, FAN NO. 2 AND FAN NO. 3) |

(a) Inspect the FAN NO. 1 relay, FAN NO. 2 relay and FAN NO. 3 relay.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (FAN NO. 1 relay) |

B |

| NG (FAN NO. 2 relay) |

C |

| NG (FAN NO. 3 relay) |

D |

| B |

.gif) | REPLACE FAN NO. 1 RELAY |

| C |

.gif) | REPLACE FAN NO. 2 RELAY |

| D |

.gif) | REPLACE FAN NO. 3 RELAY |

|

| 5. |

CHECK HARNESS AND CONNECTOR (FAN NO. 2 RELAY - BODY GROUND) |

| (a) Remove the FAN NO. 2 relay from the No. 1 engine room relay block and No. 1 junction block assembly. |

|

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

5 (FAN NO. 2 relay) - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 2 RELAY - BODY GROUND) |

|

| 6. |

INSPECT NO. 2 COOLING FAN MOTOR |

(a) Inspect the No. 2 cooling fan motor.

Click here .gif)

| NG | .gif) | REPLACE NO. 2 COOLING FAN MOTOR |

|

| 7. |

CHECK HARNESS AND CONNECTOR (COOLING FAN MOTOR RH - BODY GROUND) |

(a) Disconnect the A182 cooling fan motor RH connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A182-1 - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (COOLING FAN MOTOR RH - BODY GROUND) |

|

| 8. |

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY AND FAN NO. 2 RELAY - COOLING FAN MOTOR RH) |

(a) Disconnect the A182 cooling fan motor RH connector.

(b) Remove the FAN NO. 1 relay from the No. 2 relay block.

(c) Remove the FAN NO. 2 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(d) Measure the resistance according to the value(s) in the table below.

|

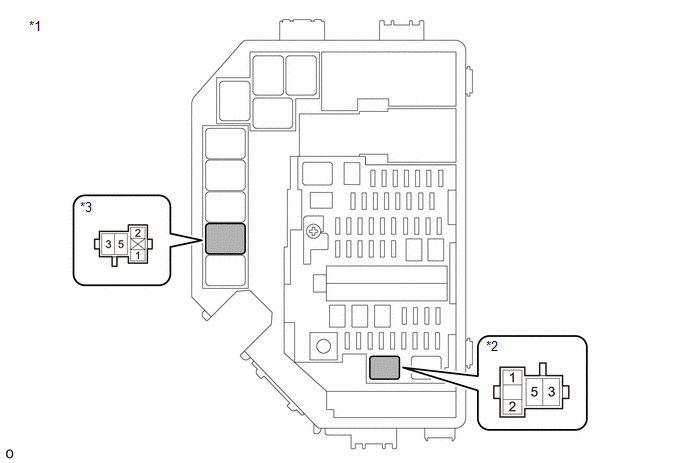

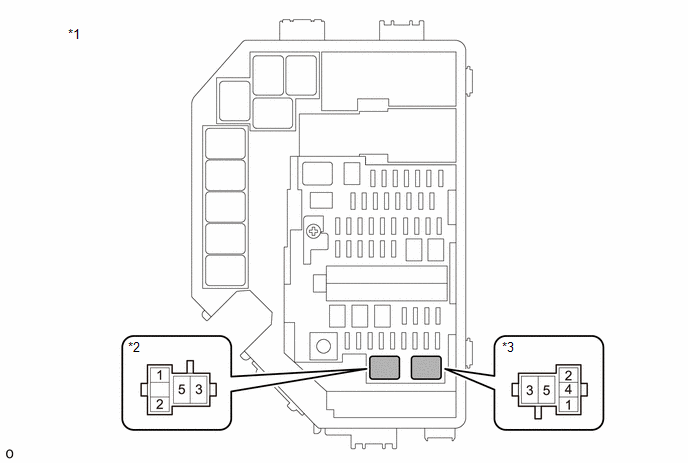

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | FAN NO. 1 Relay |

|

*3 | FAN NO. 2 Relay |

- | - |

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A182-2 - 5 (FAN NO. 1 relay) |

Always | Below 1 Ω |

|

A182-2 - 4 (FAN NO. 2 relay) |

Always | Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A182-2 or 5 (FAN NO. 1 relay) - Body ground |

Always | 10 kΩ or higher |

|

A182-2 or 4 (FAN NO. 2 relay) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY AND FAN NO. 2 RELAY - COOLING FAN MOTOR RH) |

|

| 9. |

INSPECT COOLING FAN MOTOR |

(a) Inspect the cooling fan motor.

Click here .gif)

| NG | .gif) | REPLACE COOLING FAN MOTOR |

|

| 10. |

CHECK HARNESS AND CONNECTOR (FAN NO. 2 RELAY AND FAN NO. 3 RELAY - COOLING FAN MOTOR LH) |

(a) Disconnect the A183 cooling fan motor LH connector.

(b) Remove the FAN NO. 2 relay and FAN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

|

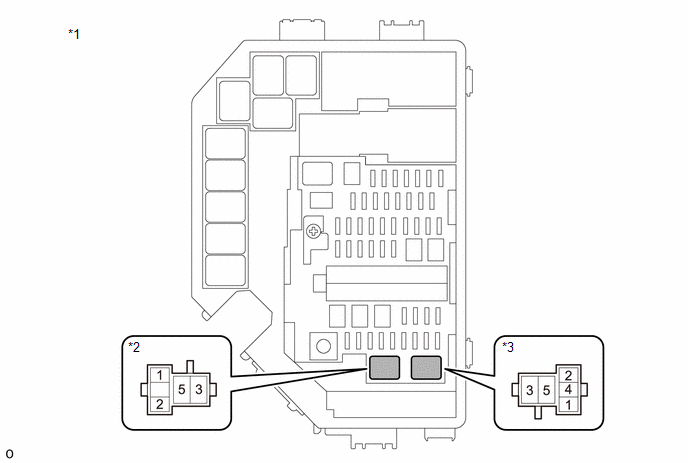

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | FAN NO. 1 Relay |

|

*3 | FAN NO. 3 Relay |

- | - |

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A183 - 3 (FAN NO. 2 relay) |

Always | Below 1 Ω |

|

A183-2 - 5 (FAN NO. 3 relay) |

Always | Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A183-1 or 3 (FAN NO. 2 relay) - Body ground |

Always | 10 kΩ or higher |

|

A183-2 or 5 (FAN NO. 3 relay) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 2 RELAY AND FAN NO. 3 RELAY - COOLING FAN MOTOR LH) |

|

| 11. |

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY - FAN NO. 2 RELAY) |

(a) Remove the FAN NO. 1 relay from the No. 2 relay block.

(b) Remove the FAN NO. 2 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the resistance according to the value(s) in the table below.

|

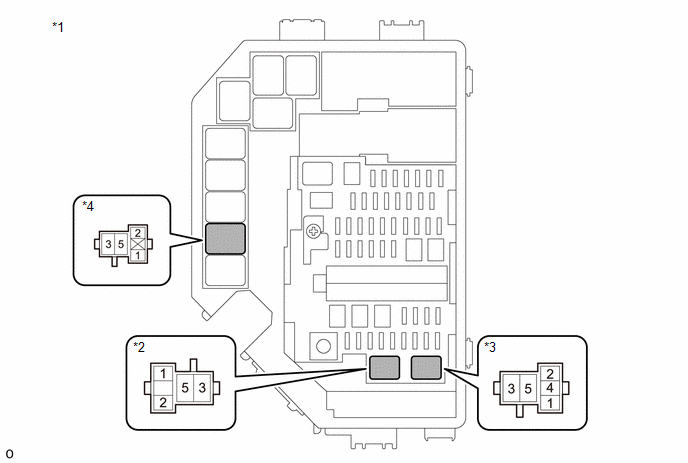

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | FAN NO. 1 Relay |

|

*3 | FAN NO. 2 Relay |

- | - |

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

1 (FAN NO. 1 relay) - 1 (FAN NO. 2 relay) |

Always | Below 1 Ω |

|

2 (FAN NO. 1 relay) - 1 (FAN NO. 2 relay) |

Always | Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

1 (FAN NO. 1 relay) or 1 (FAN NO. 2 relay) - Body ground |

Always | 10 kΩ or higher |

|

2 (FAN NO. 1 relay) or 2 (FAN NO. 2 relay) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE ECM |

| NG | .gif) | REPAIR OR REPLACE NO. 2 RELAY BLOCK |

| 12. |

INSPECT COOLING FAN RELAY (FAN NO. 1, FAN NO. 2 AND FAN NO. 3) |

(a) Inspect the FAN NO. 1 relay, FAN NO. 2 relay and FAN NO. 3 relay.

Click here

.gif)

|

Result | Proceed to |

|---|---|

|

OK | A |

|

NG (FAN NO. 1 relay) |

B |

| NG (FAN NO. 2 relay) |

C |

| NG (FAN NO. 3 relay) |

D |

| B |

.gif) | REPLACE FAN NO. 1 RELAY |

| C |

.gif) | REPLACE FAN NO. 2 RELAY |

| D |

.gif) | REPLACE FAN NO. 3 RELAY |

|

| 13. |

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY, FAN NO. 2 RELAY AND FAN NO. 3 RELAY POWER SOURCE CIRCUIT) |

(a) Remove the FAN NO. 1 relay from the No. 2 relay block.

(b) Remove the FAN NO. 2 relay and FAN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Measure the voltage according to the value(s) in the table below.

|

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | FAN NO. 1 Relay |

|

*3 | FAN NO. 2 Relay |

*4 | FAN NO. 3 Relay |

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

1 (FAN NO. 1 relay) - Body ground |

Always | 11 to 14 V |

|

1 (FAN NO. 2 relay) - Body ground |

Always | 11 to 14 V |

|

1 (FAN NO. 3 relay) - Body ground |

Always | 11 to 14 V |

| OK | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY, FAN NO. 2 RELAY AND FAN NO. 3 RELAY - ECM) |

|

| 14. |

CHECK HARNESS AND CONNECTOR (FAN NO. 1 RELAY, FAN NO. 2 RELAY AND FAN NO. 3 RELAY - NO. 1 INTEGRATION RELAY) |

(a) Remove the FAN NO. 1 relay from the No. 2 relay block.

(b) Remove the FAN NO. 2 relay and FAN NO. 3 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(c) Remove the No. 1 integration relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(d) Disconnect the 2B No. 1 integration relay connector.

(e) Measure the resistance according to the value(s) in the table below.

|

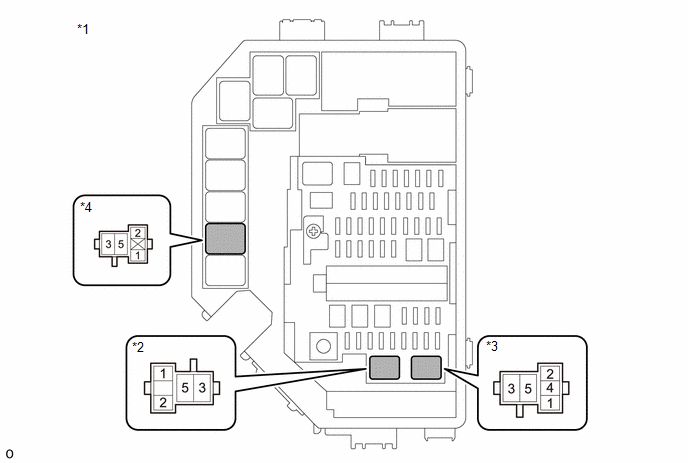

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | FAN NO. 1 Relay |

|

*3 | FAN NO. 2 Relay |

*4 | FAN NO. 3 Relay |

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

1 (FAN NO. 1 relay) - 5 (EFI-MAIN NO. 1 relay) |

Always | Below 1 Ω |

|

1 (FAN NO. 2 relay) - 5 (EFI-MAIN NO. 1 relay) |

Always | Below 1 Ω |

|

1 (FAN NO. 3 relay) - 5 (EFI-MAIN NO. 1 relay) |

Always | Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

1 (FAN NO. 1 relay) or 5 (EFI-MAIN NO. 1 relay) - Body ground |

Always | 10 kΩ or higher |

|

1 (FAN NO. 2 relay) or 5 (EFI-MAIN NO. 1 relay) - Body ground |

Always | 10 kΩ or higher |

|

1 (FAN NO. 3 relay) or 5 (EFI-MAIN NO. 1 relay) - Body ground |

Always | 10 kΩ or higher |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (FAN NO. 1 RELAY, FAN NO. 2 RELAY AND FAN NO. 3 RELAY - EFI-MAIN NO. 1 RELAY) |

|

| 15. |

CHECK HARNESS AND CONNECTOR (NO. 1 INTEGRATION RELAY POWER SOURCE CIRCUIT) |

(a) Remove the EFI-MAIN NO. 1 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the EFI-MAIN NO. 1 relay connector.

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

3 (EFI-MAIN NO. 1 relay) - Body ground |

Always | 11 to 14 V |

|

*1 | No. 1 Engine Room Relay Block and No. 1 Junction Block Assembly |

*2 | EFI-MAIN NO. 1 Relay |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (EFI-MAIN NO. 1 RELAY POWER SOURCE CIRCUIT) |

|

| 16. |

CHECK HARNESS AND CONNECTOR (EFI-MAIN NO. 1 - BODY GROUND) |

(a) Remove the EFI-MAIN NO. 1 relay from the No. 1 engine room relay block and No. 1 junction block assembly.

(b) Disconnect the EFI-MAIN NO. 1 relay connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

EFI-MAIN NO. 1 - Body ground |

Always | Below 1 Ω |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (EFI-MAIN NO. 1 RELAY - BODY GROUND) |

|

| 17. |

CHECK HARNESS AND CONNECTOR (ECM - EFI-MAIN NO. 1 RELAY) |

(a) Disconnect the A47 ECM connector.

(b) Disconnect the EFI-MAIN NO. 1 relay connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A47-15 (MREL) - 1(EFI-MAIN NO. 1 relay) |

Always | Below 1 Ω |

Standard Resistance (Check for Short):

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

A47-15 (MREL) or 1(EFI-MAIN NO. 1 relay) - Body ground |

Always | 10 kΩ or higher |

| OK | .gif) | REPLACE ECM |

| NG | .gif) | REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - EFI MAIN NO. 1 RELAY) |

.gif)