Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

|

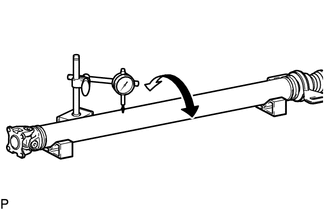

(a) Using a dial indicator, measure the runout of the intermediate shaft assembly. Maximum Runout: 0.6 mm (0.0236 in.) NOTICE: The dial indicator must be set at a right angle to the center of the intermediate shaft assembly. |

|

(b) If the runout is more than the maximum, replace the propeller shaft with center bearing assembly.

|

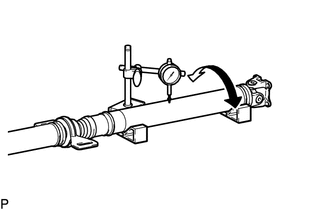

(c) Using a dial indicator, measure the runout of the propeller shaft assembly. Maximum Runout: 0.4 mm (0.0157 in.) If the runout is more than the maximum, replace the propeller shaft with center bearing assembly. NOTICE: The dial indicator must be set at a right angle to the center of the propeller shaft assembly. |

|

(d) Check that there is no excessive play and the joint part moves smoothly when moving the joint part up and down, left and right, and in the direction of the axis.