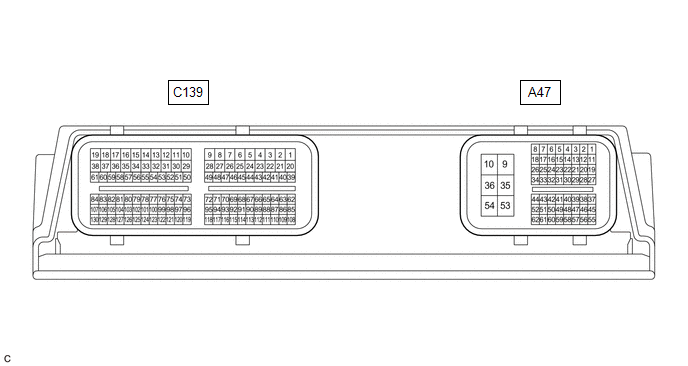

Toyota Corolla Cross: Terminals Of Ecm

TERMINALS OF ECM

HINT:

The standard voltage, resistance and waveform between each pair of the ECM terminals are shown in the table below. The appropriate conditions for checking each pair of the terminals is also indicated. The result of checks should be compared with the standard voltage, resistance and waveform for each pair of the terminals as displayed in the Specified Condition column. The illustration above can be used as a reference to identify the ECM terminal locations.

|

Terminal No. (Symbol) | Terminal Description |

Condition | Specified Condition |

|---|---|---|---|

|

A47-1 (BATT) - A47-10 (E1) |

Auxiliary battery (for measuring auxiliary battery voltage and ECM memory) |

Always | 11 to 16 V |

|

A47-2 (IGP) - A47-10 (E1) |

Ignition switch signal |

Ignition switch ON | 11 to 14 V |

|

A47-3 (VPMP) - A47-10 (E1) |

Vent valve (built into canister pump module) |

Ignition switch ON | 11 to 14 V |

|

A47-4 (MPMP) - A47-10 (E1) |

Leak detection pump (canister pump module) |

Leak detection pump OFF |

Below 3 V |

| Leak detection pump ON |

11 to 14 V | ||

|

A47-16 (FPC) - A47-10 (E1) |

Fuel pump control | Ignition switch ON |

Below 1.5 V |

|

A47-5 (CFDT) - A47-10 (E1) |

CAN communication line |

Engine stopped, Ignition switch ON |

Pulse generation (See waveform 1) |

|

A47-6 (CFDB) - A47-10 (E1) |

CAN communication line |

Engine stopped, Ignition switch ON |

Pulse generation (See waveform 4) |

|

A47-7 (CFDH) - A47-10 (E1) |

CAN communication line |

Engine stopped, Ignition switch ON |

Pulse generation (See waveform 1) |

|

A47-8 (CFDL) - A47-10 (E1) |

CAN communication line |

Engine stopped, Ignition switch ON |

Pulse generation (See waveform 4) |

|

A47-9 (+B) - A47-10 (E1) |

| Ignition switch ON |

11 to 14 V |

|

A47-10 (E1) - Body ground |

Ground | Always |

Below 1 Ω |

|

A47-11 (CCB+) - A47-10 (E1) |

Fuel vapor containment valve signal |

Ignition switch ON | Pulse generation (See waveform 2) |

|

A47-12 (CCA+) - A47-10 (E1) |

Fuel vapor containment valve signal |

Ignition switch ON | Pulse generation (See waveform 2) |

|

A47-14 (IGR) - A47-10 (E1) |

Ignition signal | Ignition switch ON |

11 to 14 V |

|

A47-15 (MREL) - A47-10 (E1) |

EFI-MAIN NO. 1 relay operation signal |

Ignition switch ON | Below 1.5 V |

|

A47-17 (NEO) - A47-10 (E1) |

Crankshaft revolution signal |

Idling with warm engine |

Pulse generation (See waveform 3) |

|

A47-19 (CCB-) - A47-10 (E1) |

Fuel vapor containment valve signal |

Ignition switch ON | Pulse generation (See waveform 2) |

|

A47-20 (CCA-) - A47-10 (E1) |

Fuel vapor containment valve signal |

Ignition switch ON | Pulse generation (See waveform 2) |

|

A47-24 (G2O) - A47-10 (E1) |

Camshaft revolution signal |

Idling with warm engine |

Pulse generation (See waveform 5) |

|

A47-31 (LIDO) - A47-10 (E1) |

Fuel lid courtesy switch signal |

Fuel lid closed | 11 to 14 V |

|

Fuel lid open | Below 1.0 V | ||

|

A47-34 (IREL) - A47-10 (E1) |

D INJ relay operation signal |

Ignition switch ON | Below 1.5 V |

|

A47-35 (+B2) - A47-10 (E1) |

Power source of ECM | Ignition switch ON |

11 to 14 V |

|

A47-36 (E01) - Body ground |

Ground | Always |

Below 1 Ω |

|

A47-38 (FUEL) - A47-10 (E1) |

Fuel lid opener switch signal |

Fuel lid opener switch pressed |

Below 1.0 V |

|

Fuel lid opener switch not pressed |

4.5 to 5.5 V | ||

|

A47-41 (LSTM) - A47-10 (E1) |

Fuel lid operation signal for combination meter assembly |

Multi-information display displaying "Close Fuel Lid" |

Pulse generation (See waveform 27) |

|

Multi-information display displaying "Ready to Refuel" |

Pulse generation (See waveform 28) | ||

|

Ignition switch ON | 11 to 14 V | ||

|

A47-44 (FREL) - A47-10 (E1) |

Fuel lid lock with motor assembly operation signal |

Fuel lid lock with motor assembly operating |

Below 1.0 V |

|

Fuel lid lock with motor assembly not operating |

11 to 14 V | ||

|

A47-45 (EC) - Body ground |

Ground | Always |

Below 1 Ω |

|

A47-48 (VCPP) - A47-49 (EPPM) |

Power source for canister pressure sensor (specific voltage) |

Ignition switch ON | 4.5 to 5.5 V |

|

A47-50 (PPMP) - A47-49 (EPPM) |

Canister pressure sensor (built into canister pump module) |

Ignition switch ON | 3.0 to 3.6 V |

|

A47-53 (+BD1) - A47-10 (E1) |

Power source of ECU (injector driver) |

Ignition switch ON | 11 to 14 V |

|

A47-54 (E1D1) - Body ground |

Ground | Always |

Below 1 Ω |

|

A47-55 (PTNK) - A47-56 (EPTK) |

Fuel tank pressure sensor signal |

Engine stopped, Ignition switch ON |

0.27 to 4.73 V |

|

A47-57 (VPTK) - A47-56 (EPTK) |

Power source of fuel tank pressure sensor (specific voltage) |

Engine stopped, Ignition switch ON |

4.75 to 5.25 V |

|

C139-1 (M-) - A47-10 (E1) |

Throttle actuator operation signal (negative signal) |

Idling with warm engine |

Pulse generation (See WAVEFORM 6) |

|

C139-2 (M+) - A47-10 (E1) |

Throttle actuator operation signal (positive terminal) |

Idling with warm engine |

Pulse generation (See WAVEFORM 7) |

|

C139-3 (EGA+) - A47-10 (E1) |

EGR valve assembly operation signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 8) |

|

C139-4 (EGA-) - A47-10 (E1) |

EGR valve assembly operation signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 8) |

|

C139-5 (EGB-) - A47-10 (E1) |

EGR valve assembly operation signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 8) |

|

C139-6 (EGB+) - A47-10 (E1) |

EGR valve assembly operation signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 8) |

|

C139-8 (HA1B) - A47-10 (E1) |

Air fuel ratio sensor (sensor 2) heater operation signal |

Ignition switch ON | 11 to 14 V |

|

Idling with cold engine |

Pulse generation (See WAVEFORM 9) | ||

|

C139-9 (HA1A) - A47-10 (E1) |

Air fuel ratio sensor (sensor 1) heater operation signal |

Ignition switch ON | 11 to 14 V |

|

Idling with cold engine |

Pulse generation (See WAVEFORM 10) | ||

|

C139-10 (#2D-) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 2 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-11 (#2D+) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 2 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-12 (#3D+) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 3 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-13 (#3D-) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 3 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-14 (#4D-) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 4 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-15 (#4D+) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 4 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-16 (#1D+) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 1 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-17 (#1D-) - A47-10 (E1) |

Direct fuel injector assembly signal (No. 1 cylinder) |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 11) |

|

C139-18 (FP1-) - A47-10 (E1) |

Fuel pump assembly (for high pressure side) signal |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 12) |

|

C139-19 (FP1+) - A47-10 (E1) |

Fuel pump assembly (for high pressure side) signal |

Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

Pulse generation (See WAVEFORM 12) |

|

C139-20 (VOP-) - A47-10 (E1) |

Oil pressure control valve operation signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 13) |

|

C139-21 (VOP+) - A47-10 (E1) |

Oil pressure control valve operation signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 13) |

|

C139-26 (OE1+) - C139-25 (OE1-) |

Cam timing oil control solenoid assembly operation signal |

Idling | Pulse generation (See WAVEFORM 14) |

|

C139-28 (EDT1) - A47-10 (E1) |

Cam timing control motor with EDU assembly signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 15) |

|

C139-46 (IGT4) - A47-10 (E1) |

No. 4 ignition coil assembly signal (ignition signal) |

Idling with warm engine |

Pulse generation (See WAVEFORM 16) |

|

C139-47 (IGT3) - A47-10 (E1) |

No. 3 ignition coil assembly signal (ignition signal) |

Idling with warm engine |

Pulse generation (See WAVEFORM 16) |

|

C139-48 (IGT2) - A47-10 (E1) |

No. 2 ignition coil assembly signal (ignition signal) |

Idling with warm engine |

Pulse generation (See WAVEFORM 16) |

|

C139-49 (IGT1) - A47-10 (E1) |

No. 1 ignition coil assembly signal (ignition signal) |

Idling with warm engine |

Pulse generation (See WAVEFORM 16) |

|

C139-50 (WPO) - A47-10 (E1) |

Electric water pump assembly signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 17) |

|

C139-51 (WPI) - A47-10 (E1) |

Electric water pump assembly signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 18) |

|

C139-66 (PRG) - A47-10 (E1) |

Purge VSV operation signal |

Ignition switch ON | 11 to 14 V |

|

Idling with warm engine, under purge control |

Pulse generation (See WAVEFORM 19) | ||

|

C139-70 (EMR1) - A47-10 (E1) |

Cam timing control motor with EDU assembly signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 20) |

|

C139-71 (EMF1) - A47-10 (E1) |

Cam timing control motor with EDU assembly signal |

Idling with warm engine |

Below 5.0 V |

|

C139-72 (EMD1) - A47-10 (E1) |

Cam timing control motor with EDU assembly signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 21) |

|

C139-73 (#40) - A47-10 (E1) |

Port fuel injector assembly signal (No. 4 cylinder) |

Idling with warm engine (Data List item "Injection Mode" displaying "Port") |

Pulse generation (See WAVEFORM 22) |

|

C139-74 (#30) - A47-10 (E1) |

Port fuel injector assembly signal (No. 3 cylinder) |

Idling with warm engine (Data List item "Injection Mode" displaying "Port") |

Pulse generation (See WAVEFORM 22) |

|

C139-75 (#20) - A47-10 (E1) |

Port fuel injector assembly signal (No. 2 cylinder) |

Idling with warm engine (Data List item "Injection Mode" displaying "Port") |

Pulse generation (See WAVEFORM 22) |

|

C139-76 (#10) - A47-10 (E1) |

Port fuel injector assembly signal (No. 1 cylinder) |

Idling with warm engine (Data List item "Injection Mode" displaying "Port") |

Pulse generation (See WAVEFORM 22) |

|

C139-78 (VCVG) - A47-10 (E1) |

Power source of mass air flow meter sub-assembly (specific voltage) |

Ignition switch ON | 4.8 to 5.2 V |

|

C139-84 (VCPF) - A47-10 (E1) |

Power source of No. 2 fuel pressure sensor (for low pressure side) (specific voltage) |

Ignition switch ON | 4.75 to 5.25 V |

|

C139-87 (VTA2) - C139-110 (ETA) |

Throttle position sensor signal (for sensor malfunction detection) |

Engine stopped, Ignition switch ON, accelerator pedal fully released |

2.1 to 3.1 V |

|

C139-88 (VCV1) - A47-10 (E1) |

Power source of camshaft position sensor (for intake camshaft) (specific voltage) |

Ignition switch ON | 4.5 to 5.5 V |

|

C139-90 (VV1+) - C139-89 (VV1-) |

Camshaft position sensor (for intake camshaft) signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 23) |

|

C139-91 (EV1+) - C139-114 (EV1-) |

Camshaft position sensor (for exhaust camshaft) signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 23) |

|

C139-93 (NE+) - C139-115 (NE-) |

Crankshaft position sensor signal |

Idling with warm engine |

Pulse generation (See WAVEFORM 24) |

|

C139-94 (A1A-) - A47-10 (E1) |

Air fuel ratio sensor (sensor 1) signal |

Ignition switch ON | 1.24 to 4.22 V |

|

C139-95 (A1A+) - A47-10 (E1) |

Air fuel ratio sensor (sensor 1) signal |

Ignition switch ON | 1.46 to 4.22 V |

|

C139-97 (PR) - C139-96 (EPR) |

Fuel pressure sensor (for high pressure side) signal |

Idling with warm engine |

0.5 to 4.5 V |

|

C139-98 (VCPR) - C139-96 (EPR) |

Power source of fuel pressure sensor (for high pressure side) (specific voltage) |

Ignition switch ON | 4.75 to 5.25 V |

|

C139-99 (VCPE) - C139-100 (EPEO) |

Power source of engine oil pressure sensor (specific voltage) |

Ignition switch ON | 4.5 to 5.5 V |

|

C139-101 (VG) - C139-79 (E2G) |

Mass air flow meter sub-assembly signal |

Ignition switch ON | Pulse generation (See WAVEFORM 25) |

|

C139-102 (THA) - C139-79 (E2G) |

Intake air temperature sensor (mass air flow meter sub-assembly) signal |

Idling, intake air temperature 0 to 80°C (32 to 176°F) |

0.5 to 3.4 V |

|

C139-107 (PFL) - C139-61 (EPFL) |

No. 2 fuel pressure sensor (for low pressure side) signal |

Idling with warm engine |

0.57 to 4.88 V |

|

C139-108 (VTA1) - C139-110 (ETA) |

Throttle position sensor signal (for engine control) |

Engine stopped, Ignition switch ON, accelerator pedal fully released |

0.6 to 1.1 V |

|

C139-109 (VCTA) - C139-110 (ETA) |

Power source of throttle position sensor (specific voltage) |

Engine stopped, Ignition switch ON |

4.5 to 5.5 V |

|

C139-111 (KNK1) - C139-112 (EKNK) |

Knock control sensor signal |

Engine speed maintained at 2500 rpm after warming up engine |

Pulse generation (See WAVEFORM 26) |

|

C139-113 (VCE1) - A47-10 (E1) |

Power source of camshaft position sensor (for exhaust camshaft) (specific voltage) |

Ignition switch ON | 4.5 to 5.5 V |

|

C139-116 (VCNE) - A47-10 (E1) |

Power source of crankshaft position sensor (specific voltage) |

Ignition switch ON | 4.5 to 5.5 V |

|

C139-117 (A1B-) - A47-10 (E1) |

Air fuel ratio sensor (sensor 2) signal |

Ignition switch ON | 1.17 to 4.49 V |

|

C139-118 (A1B+) - A47-10 (E1) |

Air fuel ratio sensor (sensor 2) signal |

Ignition switch ON | 1.53 to 5.96 V |

|

C139-120 (PIM) - C139-119 (EPIM) |

E.F.I. vacuum sensor assembly signal |

Ignition switch ON | 0.95 to 4.25 V |

|

C139-121 (VCPM) - C139-119 (EPIM) |

Power source of E.F.I. vacuum sensor assembly (specific voltage) |

Ignition switch ON | 4.75 to 5.25 V |

|

C139-122 (PEO) - C139-100 (EPEO) |

Engine oil pressure sensor signal |

Idling with warm engine |

0.5 to 4.5 V |

|

C139-123 (THEO) - C139-100 (EPEO) |

Engine oil temperature sensor signal |

Ignition switch ON | 0.54 to 4.86 V |

|

C139-125 (THW) - C139-124 (ETHW) |

Engine coolant temperature sensor signal |

Idling, engine coolant temperature 75 to 100°C (167 to 212°F) |

0.2 to 1.0 V |

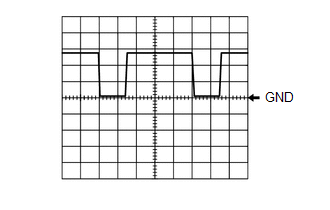

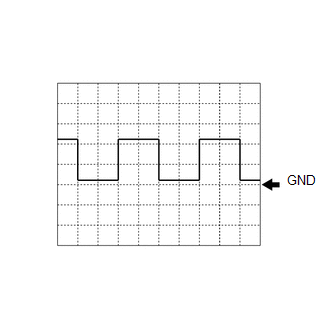

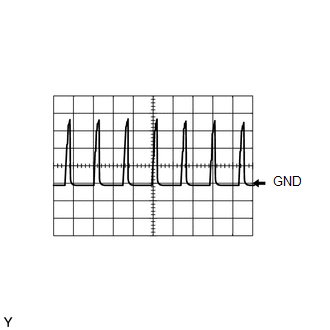

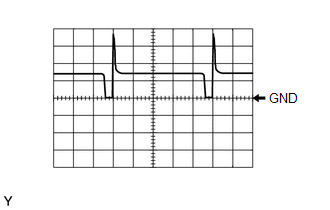

WAVEFORM 1

CAN Communication Signal (Reference)

CAN Communication Signal (Reference) |

ECM Terminal Name | Between CFDH and E1 Between CFDT and E1 |

| Tester Range |

1 V/DIV., 10 μs./DIV. |

| Condition |

Engine stopped, Ignition switch ON |

HINT:

The waveform varies depending on the CAN communication signal.

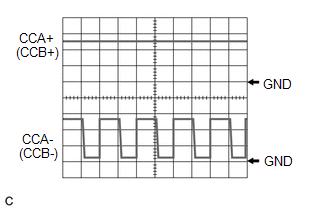

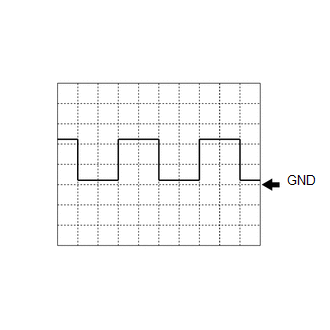

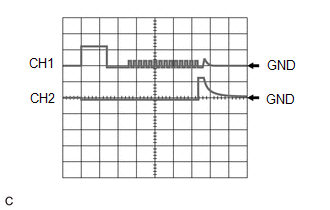

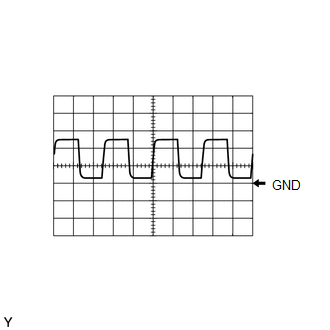

WAVEFORM 2

Fuel Vapor-containment Valve Operation Signal

Fuel Vapor-containment Valve Operation Signal |

ECM Terminal Name | CH1: Between CCA+ and E1 CH2: Between CCA- and E1 |

|

CH1: Between CCB+ and E1 CH2: Between CCB- and E1 | |

|

Tester Range | 5 V/DIV., 5 μs./DIV. |

|

Condition | Ignition switch ON |

HINT:

When the fuel vapor-containment valve is operating, a waveform is produced at each terminal.

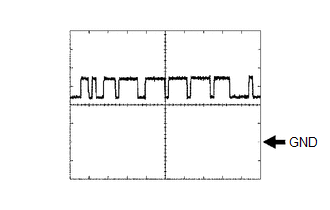

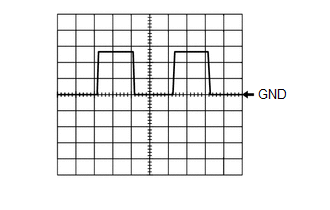

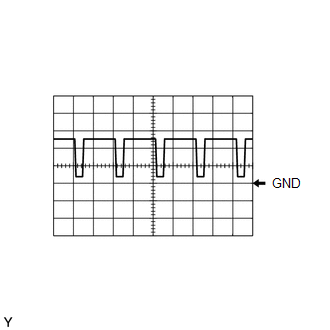

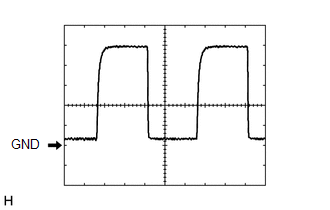

WAVEFORM 3

Crankshaft Revolution Signal from ECM to Inverter with Converter Assembly

Crankshaft Revolution Signal from ECM to Inverter with Converter Assembly |

ECM Terminal Name | Between NEO and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

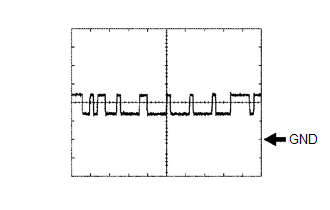

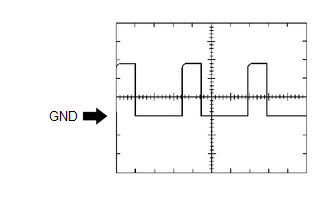

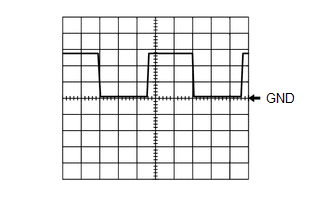

WAVEFORM 4

CAN Communication Signal (Reference)

CAN Communication Signal (Reference) |

ECM Terminal Name | Between CFDL and E1 Between CFDB and E1 |

| Tester Range |

1 V/DIV., 10 μs./DIV. |

| Condition |

Engine stopped, Ignition switch ON |

HINT:

The waveform varies depending on the CAN communication signal.

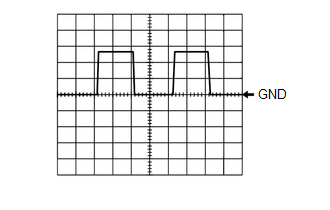

WAVEFORM 5

Camshaft Revolution Signal from ECM to Inverter with Converter Assembly

Camshaft Revolution Signal from ECM to Inverter with Converter Assembly |

ECM Terminal Name | Between G2O and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

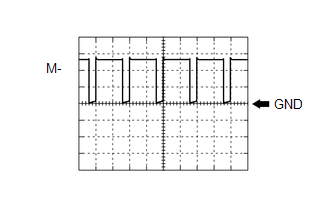

WAVEFORM 6

Throttle Actuator Operation Signal (Negative Terminal)

Throttle Actuator Operation Signal (Negative Terminal) |

ECM Terminal Name | Between M- and E1 |

|

Tester Range | 5 V/DIV., 1 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The duty ratio varies depending on the throttle actuator operation.

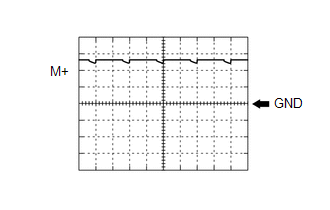

WAVEFORM 7

Throttle Actuator Operation Signal (Positive Terminal)

Throttle Actuator Operation Signal (Positive Terminal) |

ECM Terminal Name | Between M+ and E1 |

|

Tester Range | 5 V/DIV., 1 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The duty ratio varies depending on the throttle actuator operation.

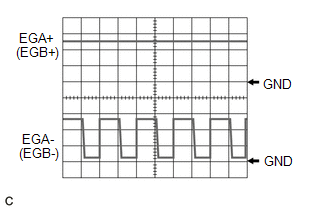

WAVEFORM 8

EGR Valve Assembly Operation Signal

EGR Valve Assembly Operation Signal |

ECM Terminal Name | CH1: Between EGA+ and E1 CH2: Between EGA- and E1 |

|

CH1: Between EGB+ and E1 CH2: Between EGB- and E1 | |

|

Tester Range | 5 V/DIV., 5 μs./DIV. |

|

Condition | Idling with warm engine |

HINT:

When the EGR valve assembly is operating, a waveform is produced at each terminal.

WAVEFORM 9

Air Fuel Ratio Sensor (Sensor 2) Heater Operation Signal

Air Fuel Ratio Sensor (Sensor 2) Heater Operation Signal |

ECM Terminal Name | Between HA1B and E1 |

|

Tester Range | 5 V/DIV., 10 ms./DIV. |

|

Condition | Idling with cold engine |

WAVEFORM 10

Air Fuel Ratio Sensor (Sensor 1) Heater Operation Signal

Air Fuel Ratio Sensor (Sensor 1) Heater Operation Signal |

ECM Terminal Name | Between HA1A and E1 |

|

Tester Range | 5 V/DIV., 10 ms./DIV. |

|

Condition | Idling with cold engine |

WAVEFORM 11

No. 1 (to No. 4) Direct Fuel Injector Assembly Signal

No. 1 (to No. 4) Direct Fuel Injector Assembly Signal |

ECM Terminal Name | CH1: Between #1D+ and E1 CH2: Between #1D- and E1 |

|

CH1: Between #2D+ and E1 CH2: Between #2D- and E1 | |

|

CH1: Between #3D+ and E1 CH2: Between #3D- and E1 | |

|

CH1: Between #4D+ and E1 CH2: Between #4D- and E1 | |

|

Tester Range | 50 V/DIV., 200 μs./DIV. |

|

Condition | Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

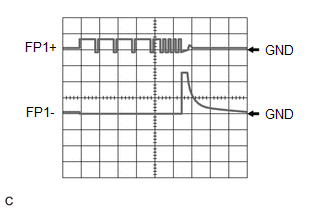

WAVEFORM 12

Fuel Pump Assembly (for High Pressure Side) Signal

Fuel Pump Assembly (for High Pressure Side) Signal |

ECM Terminal Name | CH1: Between FP1+ and E1 CH2: Between FP1- and E1 |

| Tester Range |

20 V/DIV., 500 μs./DIV. |

|

Condition | Idling with warm engine, Data List item "Injection Mode" displaying "Direct" |

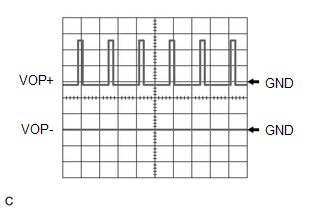

WAVEFORM 13

Oil Pressure Control Valve Operation Signal

Oil Pressure Control Valve Operation Signal |

ECM Terminal Name | CH1: Between VOP+ and E1 CH2: Between VOP- and E1 |

| Tester Range |

5 V/DIV., 20 ms./DIV. |

| Condition |

Idling with warm engine |

WAVEFORM 14

Cam Timing Oil Control Solenoid Assembly Operation Signal

Cam Timing Oil Control Solenoid Assembly Operation Signal |

ECM Terminal Name | Between OE1+ and OE1- |

|

Tester Range | 5 V/DIV., 1 ms./DIV. |

|

Condition | Idling |

WAVEFORM 15

Cam Timing Control Motor with EDU Assembly Signal (EDT Signal)|

ECM Terminal Name | Between EDT1 and E1 |

|

Tester Range | 1 V/DIV., 5 ms./DIV. |

|

Condition | Idling with warm engine |

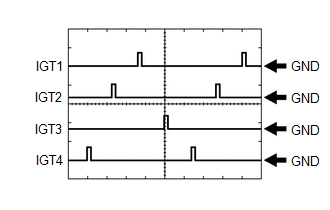

WAVEFORM 16

Ignition Coil Assembly Signal (IGT Signal)

Ignition Coil Assembly Signal (IGT Signal) |

ECM Terminal Name | Between IGT (1 to 4) and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

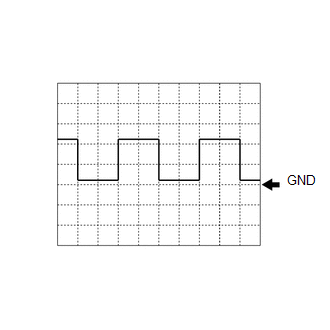

WAVEFORM 17

Engine Water Pump Assembly Signal (from ECM to Engine Water Pump Assembly)

Engine Water Pump Assembly Signal (from ECM to Engine Water Pump Assembly) |

ECM Terminal Name | Between WPO and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The duty ratio varies depending on the engine water pump assembly speed.

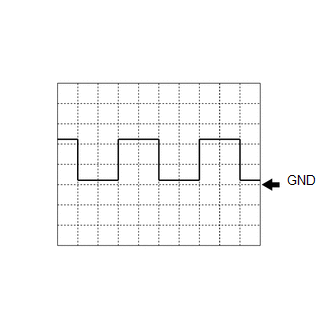

WAVEFORM 18

Engine Water Pump Assembly Signal (from Engine Water Pump Assembly to ECM)

Engine Water Pump Assembly Signal (from Engine Water Pump Assembly to ECM) |

ECM Terminal Name | Between WPI and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine water pump assembly speed increases.

WAVEFORM 19

Purge VSV Operation Signal

Purge VSV Operation Signal |

ECM Terminal Name | Between PRG and E1 |

|

Tester Range | 10 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine, under purge control |

HINT:

If the waveform is not similar to the illustration, check the waveform again after idling for 10 minutes or more.

WAVEFORM 20

Cam Timing Control Motor with EDU Assembly Signal (EMR Signal)|

ECM Terminal Name | Between EMR1 and E1 |

|

Tester Range | 2 V/DIV., 5 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

WAVEFORM 21

Cam Timing Control Motor with EDU Assembly Signal (EMD Signal)|

ECM Terminal Name | Between EMD1 and E1 |

|

Tester Range | 2 V/DIV., 100 ms./DIV. |

|

Condition | Idling with warm engine |

WAVEFORM 22

No. 1 (to No. 4) Port Fuel Injector Assembly Signal

No. 1 (to No. 4) Port Fuel Injector Assembly Signal |

ECM Terminal Name | Between #10 (to #40) and E1 |

|

Tester Range | 20 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine (Data List item "Injection Mode" displaying "Port") |

HINT:

- The wavelength becomes shorter as the engine speed increases.

- When the port injection injectors are operating, Port is displayed for Injection Mode of the Data List.

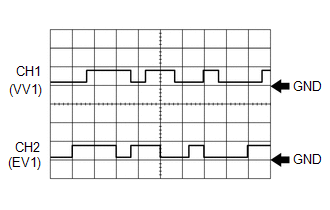

WAVEFORM 23

Camshaft Position Sensor Signal

Camshaft Position Sensor Signal |

ECM Terminal Name | CH1: Between VV1+ and VV1- CH2: Between EV1+ and EV1- |

| Tester Range |

5 V/DIV., 20 ms./DIV. |

| Condition |

Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

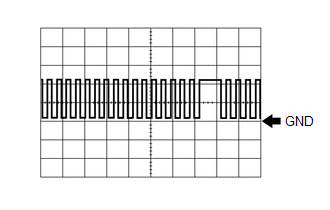

WAVEFORM 24

Crankshaft Position Sensor Signal

Crankshaft Position Sensor Signal |

ECM Terminal Name | Between NE+ and NE- |

|

Tester Range | 2 V/DIV., 20 ms./DIV. |

|

Condition | Idling with warm engine |

HINT:

The wavelength becomes shorter as the engine speed increases.

WAVEFORM 25

Mass Air Flow Meter Sub-assembly Signal

Mass Air Flow Meter Sub-assembly Signal |

ECM Terminal Name | Between VG and E2G |

|

Tester Range | 1 V/DIV., 100 μs./DIV. |

|

Condition | Ignition switch ON |

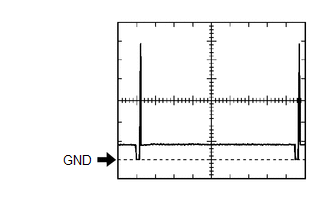

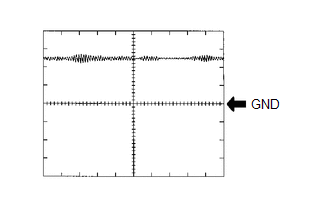

WAVEFORM 26

Knock Control Sensor Signal

Knock Control Sensor Signal |

ECM Terminal Name | Between KNK1 and EKNK |

|

Tester Range | 1 V/DIV., 1 ms./DIV. |

|

Condition | Engine speed maintained at 2500 rpm after warming up engine |

HINT:

- The wavelength becomes shorter as the engine speed increases.

- The waveforms and amplitudes displayed differ slightly depending on the vehicle.

WAVEFORM 27

Fuel Lid Operation Signal for Combination Meter Assembly|

ECM Terminal Name | Between LSTM and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Multi-information display displaying "Close Fuel Lid" |

WAVEFORM 28

Fuel Lid Operation Signal for Combination Meter Assembly|

ECM Terminal Name | Between LSTM and E1 |

|

Tester Range | 5 V/DIV., 20 ms./DIV. |

|

Condition | Multi-information display displaying "Ready to Refuel" |