Toyota Corolla Cross: Microphone Circuit

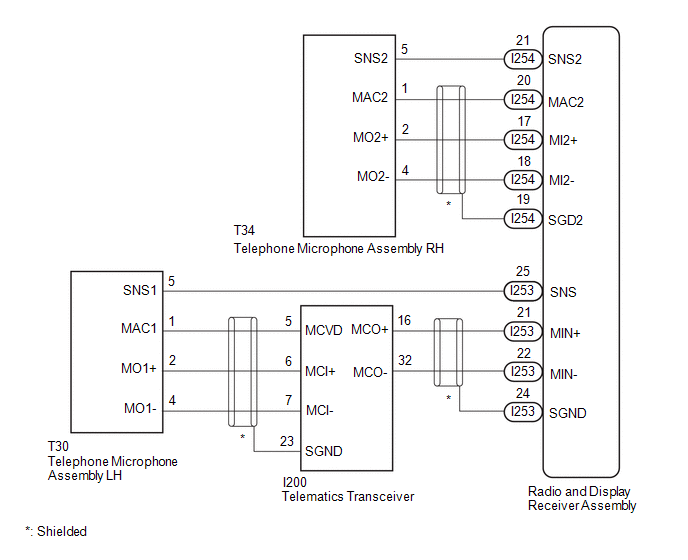

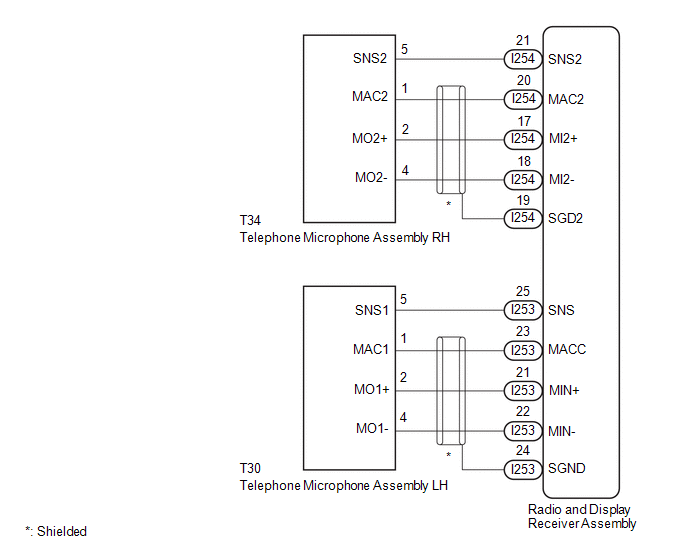

WIRING DIAGRAM

w/ Telematics Transceiver w/o Telematics Transceiver

w/o Telematics Transceiver

CAUTION / NOTICE / HINT

NOTICE:

- When replacing the telematics transceiver, make sure to replace it with a new one.

- Depending on the parts that are replaced during vehicle inspection or

maintenance, performing initialization, registration or calibration may

be needed.

Click here

.gif)

PROCEDURE

|

1. |

CHECK MODEL |

|

Result |

Proceed to |

|---|---|

|

w/ Telematics Transceiver |

A |

|

w/o Telematics Transceiver |

B |

| B | .gif)

|

GO TO STEP 15 |

|

|

2. |

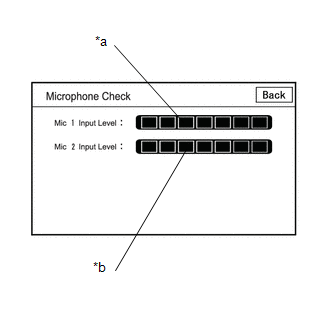

CHECK MICROPHONE |

|

(a) Enter diagnostic mode. Click here |

|

(b) Select "Function Check/Setting" from the "Service Menu" screen.

(c) Select "Microphone Check" from the "Function Check/Setting I" screen.

(d) Speak into each microphone assembly and check the microphone input level gauge display.

OK:

The microphone input levels of the gauge change in accordance with the voice.

|

Result |

Proceed to |

|---|---|

|

Microphone input levels change for microphone 1 and 2 |

A |

|

Microphone input level does not change for microphone 1 |

B |

|

Microphone input level does not change for microphone 2 |

C |

| A | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

| C | .gif)

|

GO TO STEP 12 |

|

|

3. |

CHECK TELEMATICS TRANSCEIVER (MICROPHONE POWER SOURCE AND BODY GROUND) |

HINT:

Measure the connector of the telematics transceiver while it is connected.

|

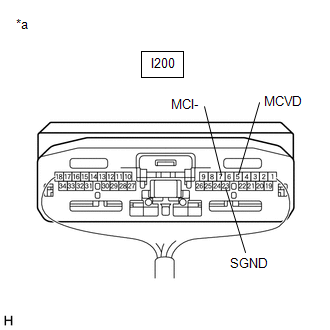

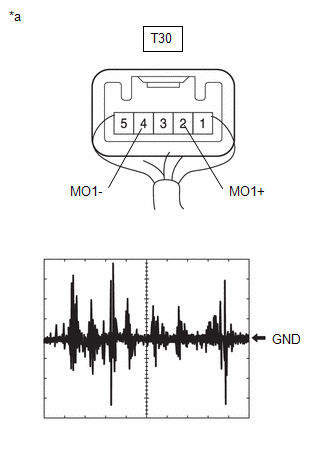

*a |

Component with harness connected (Telematics Transceiver) |

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I200-7 (MCI-) - Body ground |

Always |

Below 1 Ω |

|

I200-23 (SGND) - Body ground |

Always |

Below 1 Ω |

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I200-5 (MCVD) - Body ground |

Ignition switch ON |

7.5 to 8.5 V |

| NG | .gif)

|

GO TO STEP 10 |

|

|

4. |

CHECK TELEMATICS TRANSCEIVER (OUTPUT TO RADIO AND DISPLAY RECEIVER ASSEMBLY) |

HINT:

Measure the connector of the telematics transceiver while it is connected.

|

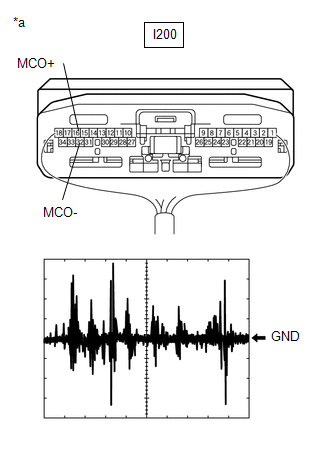

*a |

Component with harness connected (Telematics Transceiver) |

(a) Measure the resistance according to the value(s) in the table below.

|

Item |

Condition |

|---|---|

|

Tester Connection |

I200-16 (MCO+) - I200-32 (MCO-) |

|

Tool setting |

50 mV/DIV., 500 ms/DIV. |

|

Vehicle condition |

|

OK:

The waveform is similar to that shown in the illustration.

HINT:

- The oscilloscope waveform shown in the illustration is an example for reference only.

- In order to ensure that a consistent sound level is input to the microphone, use a digital voice recorder, etc., to play back sound in the same location with respect to the microphone.

|

Result |

Proceed to |

|---|---|

|

A waveform synchronized with voice signals is output |

A |

|

A waveform synchronized with voice signals is not output |

B |

| B | .gif)

|

GO TO STEP 6 |

|

|

5. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEMATICS TRANSCEIVER) |

(a) Disconnect the I253 radio and display receiver assembly connector.

(b) Disconnect the I200 telematics transceiver connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I253-21 (MIN+) - I200-16 (MCO+) |

Always |

Below 1 Ω |

|

I253-22 (MIN-) - I200-32 (MCO-) |

Always |

Below 1 Ω |

|

I253-21 (MIN+) - Body ground |

Always |

10 kΩ or higher |

|

I253-22 (MIN-) - Body ground |

Always |

10 kΩ or higher |

|

I253-24 (SGND) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

6. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEMATICS TRANSCEIVER) |

(a) Disconnect the I253 radio and display receiver assembly connector.

(b) Disconnect the I200 telematics transceiver connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I253-21 (MIN+) - I200-16 (MCO+) |

Always |

Below 1 Ω |

|

I253-22 (MIN-) - I200-32 (MCO-) |

Always |

Below 1 Ω |

|

I253-21 (MIN+) - Body ground |

Always |

10 kΩ or higher |

|

I253-22 (MIN-) - Body ground |

Always |

10 kΩ or higher |

|

I253-24 (SGND) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

7. |

CHECK HARNESS AND CONNECTOR (TELEMATICS TRANSCEIVER - TELEPHONE MICROPHONE ASSEMBLY LH) |

(a) Disconnect the I200 telematics transceiver connector.

(b) Disconnect the T30 telephone microphone assembly LH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I200-5 (MCVD) - T30-1 (MAC1) |

Always |

Below 1 Ω |

|

I200-6 (MCI+) - T30-2 (MO1+) |

Always |

Below 1 Ω |

|

I200-7 (MCI-) - T30-4 (MO1-) |

Always |

Below 1 Ω |

|

I200-5 (MCVD) - Body ground |

Always |

10 kΩ or higher |

|

I200-6 (MCI+) - Body ground |

Always |

10 kΩ or higher |

|

I200-7 (MCI-) - Body ground |

Always |

10 kΩ or higher |

|

I200-23 (SGND) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

8. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEPHONE MICROPHONE ASSEMBLY LH) |

(a) Disconnect the I253 radio and display receiver assembly connector.

(b) Disconnect the T30 telephone microphone assembly LH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I253-25 (SNS) - T30-5 (SNS1) |

Always |

Below 1 Ω |

|

I253-25 (SNS) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

9. |

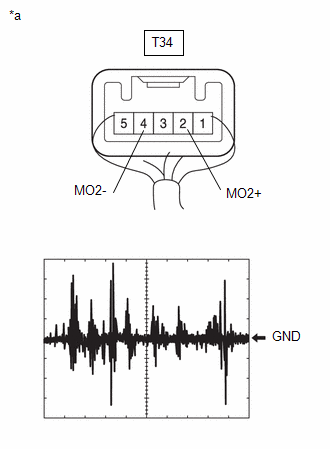

CHECK TELEPHONE MICROPHONE ASSEMBLY LH (OUTPUT TO TELEMATICS TRANSCEIVER) |

|

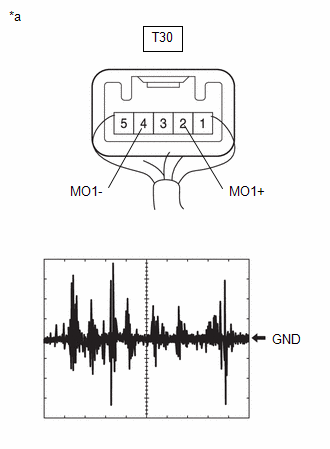

*a |

Component with harness connected (Telephone Microphone Assembly LH) |

(a) Using an oscilloscope, measure the waveform according to the condition(s) in the table below.

|

Item |

Condition |

|---|---|

|

Tester Connection |

T30-2 (MO1+) - T30-4 (MO1-) |

|

Tool setting |

50 mV/DIV., 500 ms/DIV. |

|

Vehicle condition |

|

OK:

The waveform is similar to that shown in the illustration.

HINT:

- The oscilloscope waveform shown in the illustration is an example for reference only.

- In order to ensure that a consistent sound level is input to the microphone, use a digital voice recorder, etc., to play back sound in the same location with respect to the microphone.

|

Result |

Proceed to |

|---|---|

|

A waveform synchronized with voice signals is output |

A |

|

A waveform synchronized with voice signals is not output |

B |

| A | .gif)

|

REPLACE TELEMATICS TRANSCEIVER |

| B | .gif)

|

REPLACE TELEPHONE MICROPHONE ASSEMBLY LH |

|

10. |

CHECK HARNESS AND CONNECTOR (TELEMATICS TRANSCEIVER - TELEPHONE MICROPHONE ASSEMBLY LH) |

(a) Disconnect the I200 telematics transceiver connector.

(b) Disconnect the T30 telephone microphone assembly LH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I200-5 (MCVD) - T30-1 (MAC1) |

Always |

Below 1 Ω |

|

I200-6 (MCI+) - T30-2 (MO1+) |

Always |

Below 1 Ω |

|

I200-7 (MCI-) - T30-4 (MO1-) |

Always |

Below 1 Ω |

|

I200-5 (MCVD) - Body ground |

Always |

10 kΩ or higher |

|

I200-6 (MCI+) - Body ground |

Always |

10 kΩ or higher |

|

I200-7 (MCI-) - Body ground |

Always |

10 kΩ or higher |

|

I200-23 (SGND) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

11. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEMATICS TRANSCEIVER) |

(a) Disconnect the I253 radio and display receiver assembly connector.

(b) Disconnect the I200 telematics transceiver connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I253-21 (MIN+) - I200-16 (MCO+) |

Always |

Below 1 Ω |

|

I253-22 (MIN-) - I200-32 (MCO-) |

Always |

Below 1 Ω |

|

I253-21 (MIN+) - Body ground |

Always |

10 kΩ or higher |

|

I253-22 (MIN-) - Body ground |

Always |

10 kΩ or higher |

|

I253-24 (SGND) - Body ground |

Always |

10 kΩ or higher |

| OK | .gif)

|

REPLACE TELEMATICS TRANSCEIVER |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

12. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEPHONE MICROPHONE ASSEMBLY RH) |

(a) Disconnect the I254 radio and display receiver assembly connector.

(b) Disconnect the T34 telephone microphone assembly RH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I254-17 (MI2+) - T34-2 (MO2+) |

Always |

Below 1 Ω |

|

I254-18 (MI2-) - T34-4 (MO2-) |

Always |

Below 1 Ω |

|

I254-20 (MAC2) - T34-1 (MAC2) |

Always |

Below 1 Ω |

|

I254-21 (SNS2) - T34-5 (SNS2) |

Always |

Below 1 Ω |

|

I254-17 (MI2+) - Body ground |

Always |

10 kΩ or higher |

|

I254-18 (MI2-) - Body ground |

Always |

10 kΩ or higher |

|

I254-20 (MAC2) - Body ground |

Always |

10 kΩ or higher |

|

I254-19 (SGD2) - Body ground |

Always |

10 kΩ or higher |

|

I254-21 (SNS2) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

13. |

CHECK RADIO & DISPLAY RECEIVER ASSEMBLY (MAC2, MI2-) |

(a) With the I254 radio and display receiver assembly connector connected, disconnect the T34 telephone microphone assembly RH connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T34-4 (MO2-) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T34-1 (MAC2) - Body ground |

Ignition switch ON |

7.5 to 8.5 V |

| NG | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

|

|

14. |

CHECK TELEPHONE MICROPHONE ASSEMBLY RH (OUTPUT TO RADIO AND DISPLAY RECEIVER ASSEMBLY) |

|

(a) Using an oscilloscope, measure the waveform according to the condition(s) in the table below.

OK: The waveform is similar to that shown in the illustration. HINT:

|

|

|

Result |

Proceed to |

|---|---|

|

A waveform synchronized with voice signals is output |

A |

|

A waveform synchronized with voice signals is not output |

B |

| A | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

| B | .gif)

|

REPLACE TELEPHONE MICROPHONE ASSEMBLY RH |

|

15. |

CHECK MICROPHONE |

|

(a) Enter diagnostic mode. Click here |

|

(b) Select "Function Check/Setting" from the "Service Menu" screen.

(c) Select "Microphone Check" from the "Function Check/Setting I" screen.

(d) Speak into each microphone assembly and check the microphone input level gauge display.

OK:

The microphone input levels of the gauge change in accordance with the voice.

|

Result |

Proceed to |

|---|---|

|

Microphone input levels change for microphone 1 and 2 |

A |

|

Microphone input level does not change for microphone 1 |

B |

|

Microphone input level does not change for microphone 2 |

C |

| A | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

| C | .gif)

|

GO TO STEP 19 |

|

|

16. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEPHONE MICROPHONE ASSEMBLY LH) |

(a) Disconnect the I253 radio and display receiver assembly connector.

(b) Disconnect the T30 telephone microphone assembly LH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I253-21 (MIN+) - T30-2 (MO1+) |

Always |

Below 1 Ω |

|

I253-22 (MIN-) - T30-4 (MO1-) |

Always |

Below 1 Ω |

|

I253-23 (MACC) - T30-1 (MAC1) |

Always |

Below 1 Ω |

|

I253-25 (SNS) - T30-5 (SNS1) |

Always |

Below 1 Ω |

|

I253-21 (MIN+) - Body ground |

Always |

10 kΩ or higher |

|

I253-22 (MIN-) - Body ground |

Always |

10 kΩ or higher |

|

I253-23 (MACC) - Body ground |

Always |

10 kΩ or higher |

|

I253-24 (SGND) - Body ground |

Always |

10 kΩ or higher |

|

I253-25 (SNS) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

17. |

INSPECT RADIO & DISPLAY RECEIVER ASSEMBLY (MACC, MIN-) |

(a) With the I253 radio and display receiver assembly connector connected, disconnect the T30 telephone microphone assembly LH connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T30-4 (MO1-) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T30-1 (MACC) - Body ground |

Always |

7.5 to 8.5 V |

| NG | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

|

|

18. |

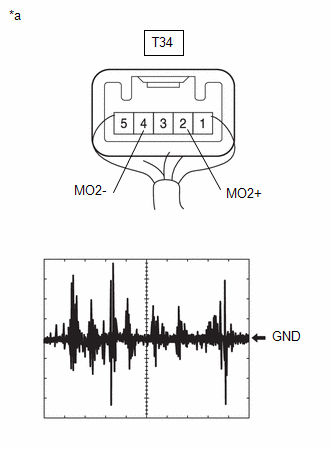

INSPECT TELEPHONE MICROPHONE ASSEMBLY LH (OUTPUT TO RADIO AND DISPLAY RECEIVER ASSEMBLY) |

|

*a |

Component with harness connected (Telephone microphone assembly LH) |

(a) Using an oscilloscope, measure the waveform according to the condition(s) in the table below.

|

Item |

Condition |

|---|---|

|

Tester Connection |

T30-2 (MO1+) - T30-4 (MO1-) |

|

Tool setting |

50 mV/DIV., 500 ms/DIV. |

|

Vehicle condition |

|

OK:

The waveform is similar to that shown in the illustration.

HINT:

- The oscilloscope waveform shown in the illustration is an example for reference only.

- In order to ensure that a consistent sound level is input to the microphone, use a digital voice recorder, etc., to play back sound in the same location with respect to the microphone.

|

Result |

Proceed to |

|---|---|

|

A waveform synchronized with voice signals is output |

A |

|

A waveform synchronized with voice signals is not output |

B |

| A | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

| B | .gif)

|

REPLACE TELEPHONE MICROPHONE ASSEMBLY LH |

|

19. |

CHECK HARNESS AND CONNECTOR (RADIO AND DISPLAY RECEIVER ASSEMBLY - TELEPHONE MICROPHONE ASSEMBLY RH) |

(a) Disconnect the I254 radio and display receiver assembly connector.

(b) Disconnect the T34 telephone microphone assembly RH connector.

(c) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

I254-17 (MI2+) - T34-2 (MO2+) |

Always |

Below 1 Ω |

|

I254-18 (MI2-) - T34-4 (MO2-) |

Always |

Below 1 Ω |

|

I254-20 (MAC2) - T34-1 (MAC2) |

Always |

Below 1 Ω |

|

I254-21 (SNS) - T34-5 (SNS2) |

Always |

Below 1 Ω |

|

I254-17 (MI2+) - Body ground |

Always |

10 kΩ or higher |

|

I254-18 (MI2-) - Body ground |

Always |

10 kΩ or higher |

|

I254-20 (MAC2) - Body ground |

Always |

10 kΩ or higher |

|

I254-19 (SGD2) - Body ground |

Always |

10 kΩ or higher |

|

I254-21 (SNS2) - Body ground |

Always |

10 kΩ or higher |

| NG | .gif)

|

REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

20. |

CHECK RADIO & DISPLAY RECEIVER ASSEMBLY (MAC2, MI2-) |

(a) With the I254 radio and display receiver assembly connector connected, disconnect the T34 telephone microphone assembly RH connector.

(b) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T34-4 (MO2-) - Body ground |

Always |

Below 1 Ω |

(c) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

T34-1 (MAC2) - Body ground |

Ignition switch ON |

7.5 to 8.5 V |

| NG | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

|

|

21. |

CHECK TELEPHONE MICROPHONE ASSEMBLY RH (OUTPUT TO RADIO AND DISPLAY RECEIVER ASSEMBLY) |

|

(a) Using an oscilloscope, measure the waveform according to the condition(s) in the table below.

OK: The waveform is similar to that shown in the illustration. HINT:

|

|

|

Result |

Proceed to |

|---|---|

|

A waveform synchronized with voice signals is output |

A |

|

A waveform synchronized with voice signals is not output |

B |

| A | .gif)

|

REPLACE RADIO & DISPLAY RECEIVER ASSEMBLY |

| B | .gif)

|

REPLACE TELEPHONE MICROPHONE ASSEMBLY RH |

.gif)