Toyota Corolla Cross: M20a-fks Oil And Oil Filter

Components

COMPONENTS

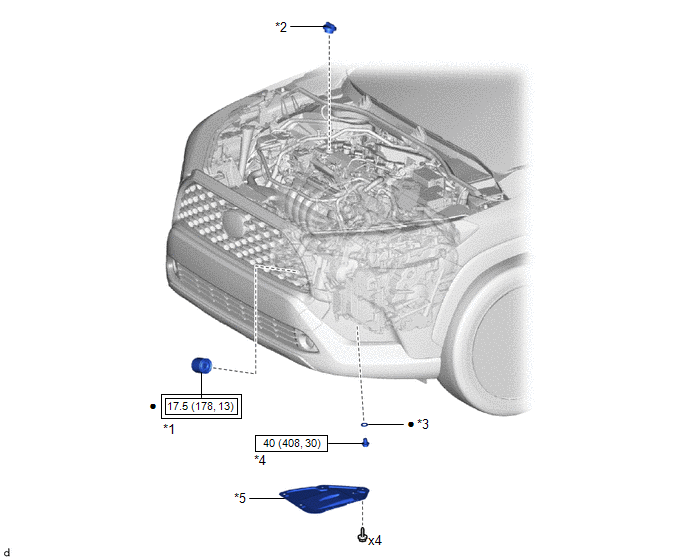

ILLUSTRATION

|

*1 |

OIL FILTER SUB-ASSEMBLY |

*2 |

OIL FILLER CAP ASSEMBLY |

|

*3 |

GASKET |

*4 |

OIL PAN DRAIN PLUG |

|

*5 |

CENTER NO. 4 ENGINE UNDER COVER |

- |

- |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping": N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● |

Non-reusable part |

- |

- |

Replacement

REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

- Prolonged and repeated contact with engine oil will result in the removal of natural oils from the skin, leading to dryness, irritation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause skin cancer.

- Wear protective clothing and gloves. Avoid contact with used oil. If contact occurs, wash your skin thoroughly with soap or waterless hand cleaner. Never use gasoline, thinners, or solvents to wash the skin.

- In order to protect the environment, dispose of used oil and used oil filters at designated disposal sites only.

PROCEDURE

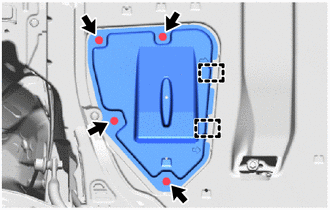

1. REMOVE CENTER NO. 4 ENGINE UNDER COVER

|

(a) Remove the 4 screws and disengage the 2 guides to remove the center No. 4 engine under cover. |

|

2. DRAIN ENGINE OIL

(a) Remove the oil filler cap assembly.

(b) Remove the oil pan drain plug and gasket, and drain the engine oil into a container.

(c) Clean the oil pan drain plug.

(d) Install a new gasket to the oil pan drain plug.

(e) Install the oil pan drain plug.

Torque:

40 N·m {408 kgf·cm, 30 ft·lbf}

3. REMOVE OIL FILTER SUB-ASSEMBLY

(a) Using SST, remove the oil filter sub-assembly.

SST: 09228-06502

4. INSTALL OIL FILTER SUB-ASSEMBLY

(a) Check and clean the oil filter sub-assembly installation surface.

(b) Apply clean engine oil to the gasket of a new oil filter sub-assembly.

(c) Lightly screw the oil filter sub-assembly into place by hand. Tighten it until the gasket contacts the seat.

(d) Using SST, tighten the oil filter sub-assembly.

SST: 09228-06502

(1) Depending on the work space available, choose from the following:

- If enough space is available, use a torque wrench to tighten the oil filter sub-assembly.

Torque:

17.5 N·m {178 kgf·cm, 13 ft·lbf}

- If not enough space is available to use a torque wrench, tighten the oil filter sub-assembly 3/4 of a turn by hand or using a common wrench.

5. ADD ENGINE OIL

(a) Add new engine oil and install the oil filler cap assembly.

Standard Oil Grade:|

Oil Grade |

Oil Viscosity (SAE) |

|---|---|

|

API grade SN "Resource-Conserving", SN PLUS "Resource-Conserving"or SP "Resource-Conserving" ;or ILSAC GF-6B multigrade engine oil |

|

|

API grade SL "Energy-Conserving", SM "Energy-Conserving", SN "Resource-Conserving", SN PLUS "Resource-Conserving"or SP "Resource-Conserving"; or ILSAC GF-6A multigrade engine oil |

|

|

Item |

Standard Condition |

|---|---|

|

Drain and refill with oil filter change |

4.6 liters (4.9 US qts, 4.0 Imp. qts) |

|

Drain and refill without oil filter change |

4.3 liters (4.5 US qts, 3.8 Imp. qts) |

|

Dry fill |

5.4 liters (5.7 US qts, 4.8 Imp. qts) |

6. INSPECT FOR ENGINE OIL LEAK

(a) Start the engine. Make sure that there are no engine oil leaks from the area that was worked on.

7. CHECK ENGINE OIL LEVEL

Click here .gif)

8. INSTALL CENTER NO. 4 ENGINE UNDER COVER

(a) Engage the 2 guide to install the center No. 4 engine under cover with the 4 screws.