Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

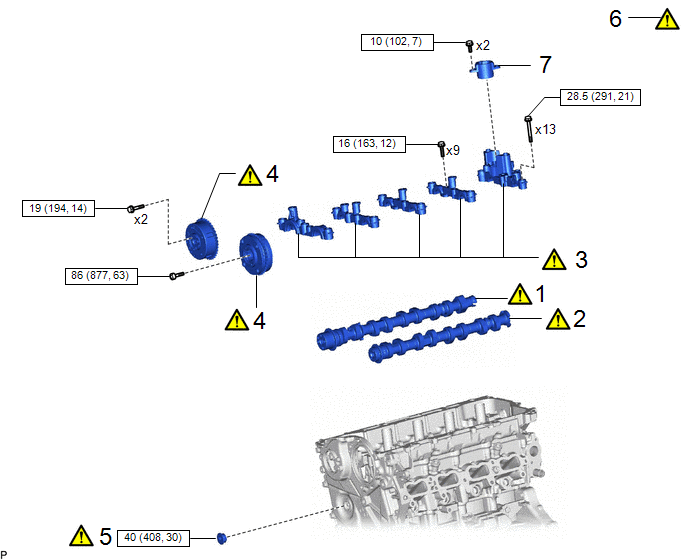

COMPONENTS (INSTALLATION)

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | EXHAUST CAMSHAFT SUB-ASSEMBLY |

- |

|

- | - |

|

2 | INTAKE CAMSHAFT SUB-ASSEMBLY |

- |

|

- | - |

|

3 | CAMSHAFT BEARING CAP |

- |

|

- | - |

|

4 | CAMSHAFT TIMING GEAR ASSEMBLY |

- |

|

- | - |

|

5 | STRAIGHT SCREW PLUG |

- |

|

- | - |

|

6 | NO. 1 CYLINDER TO TDC (COMPRESSION) |

- |

|

- | - |

|

7 | FUEL PUMP LIFTER GUIDE |

23477 | - |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

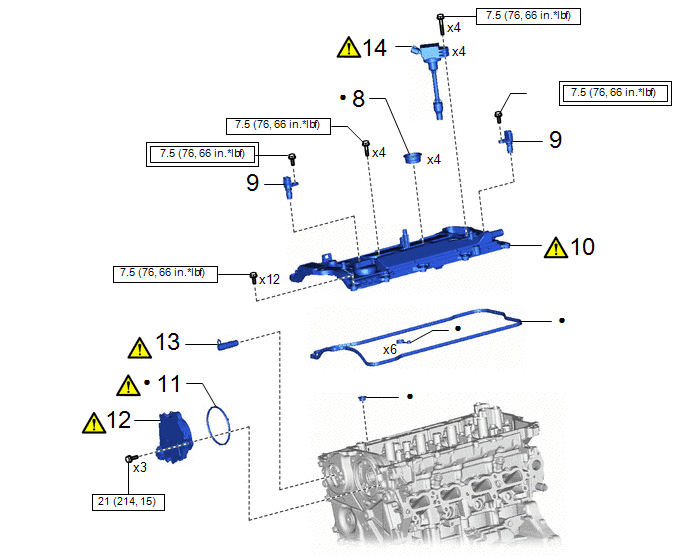

8 | SPARK PLUG TUBE GASKET |

11193 | - |

- | - |

|

9 | CAMSHAFT POSITION SENSOR |

11102A | - |

- | - |

|

10 | CYLINDER HEAD COVER SUB-ASSEMBLY |

11201 |

|

- | - |

|

11 | CAM TIMING CONTROL MOTOR O-RING |

13090E |

|

- | - |

|

12 | CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY |

13090D |

|

- | - |

|

13 | CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY) |

135A0A |

|

- | - |

|

14 | IGNITION COIL ASSEMBLY |

19500 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

★ | Precoated part |

|

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

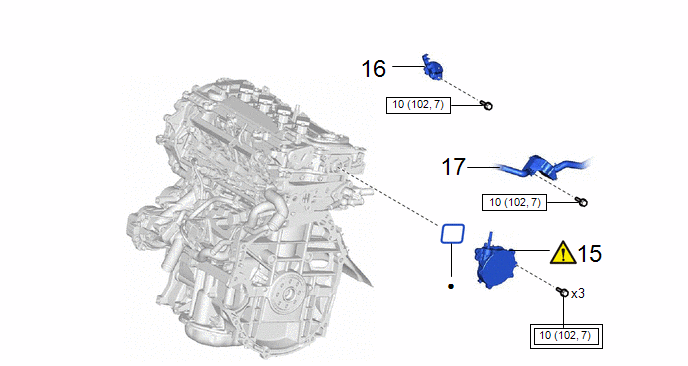

15 | VACUUM PUMP ASSEMBLY |

29300 |

|

- | - |

|

16 | NO. 3 WATER HOSE CLAMP BRACKET |

16575F | - |

- | - |

|

17 | VACUUM SURGE TANK |

25719 | - |

- | - |

|

*A | When Not Using the Engine Support Bridge |

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

- | - |

|

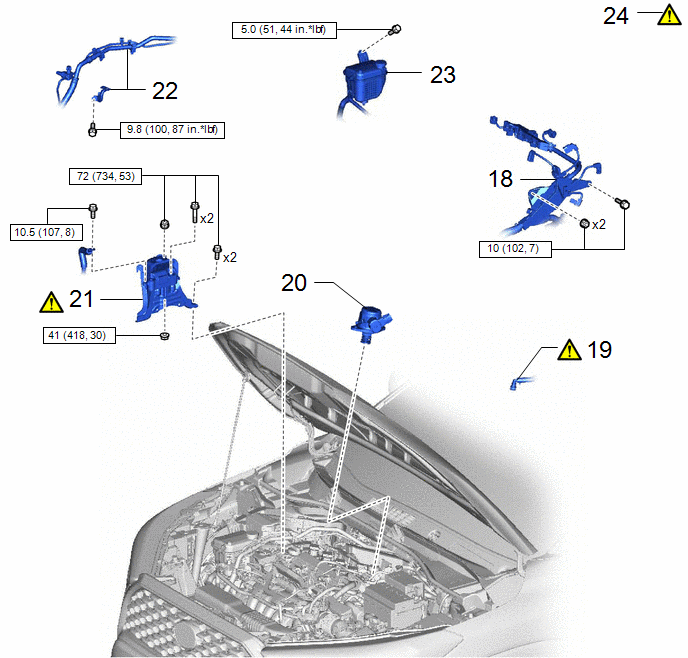

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

18 | ENGINE WIRE |

82121 | - |

- | - |

|

19 | NO. 1 VACUUM HOSE CONNECTOR |

44777 |

|

- | - |

|

20 | FUEL(ENGINE ROOM SIDE) PUMP ASSEMBLY |

23100X | - |

- | - |

|

21 | ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH |

12305 |

|

- | - |

|

22 | NO. 1 COOLER REFRIGERANT HOSE |

- | - |

- | - |

|

23 | RADIATOR RESERVE TANK ASSEMBLY |

16470 | - |

- | - |

|

24 | ENGINE SUPPORT BRIDGE |

- |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

- | - |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

PROCEDURE

1. INSTALL EXHAUST CAMSHAFT SUB-ASSEMBLY

.png) |

HINT: Perform "Inspection After Repair" after replacing the intake camshaft sub-assembly, exhaust camshaft sub-assembly, camshaft timing gear assembly and camshaft timing exhaust gear assembly. Click here |

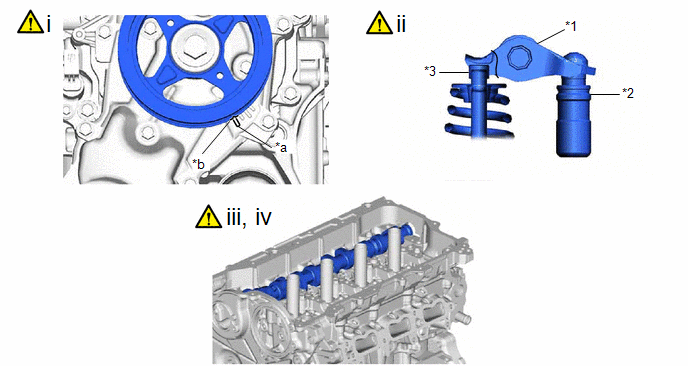

(1) Turn the crankshaft clockwise to align the timing mark (cutout) on the crankshaft pulley assembly with the "0" timing mark on the No. 2 timing chain cover assembly.

(2) Check that the No. 1 valve rocker arm sub-assembly is correctly installed as shown in the illustration.

(3) Clean the camshaft housing sub-assembly and the cams and journals of the exhaust camshaft sub-assembly, and then apply engine oil to them.

(4) Apply a light coat of engine oil to the journals of the exhaust camshaft sub-assembly and install the exhaust camshaft sub-assembly to the camshaft housing sub-assembly.

2. INSTALL INTAKE CAMSHAFT SUB-ASSEMBLY

(1) Clean the camshaft housing sub-assembly and the cams and journals of the intake camshaft sub-assembly, and then apply engine oil to them.

(2) Apply a light coat of engine oil to the journals of the exhaust camshaft sub-assembly and install the exhaust camshaft sub-assembly to the camshaft housing sub-assembly.

3. INSTALL CAMSHAFT BEARING CAP

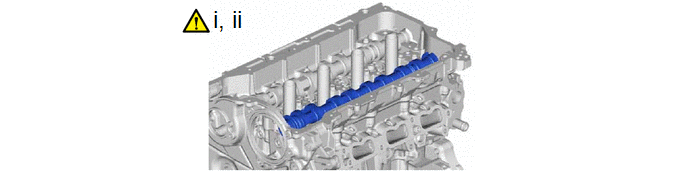

|

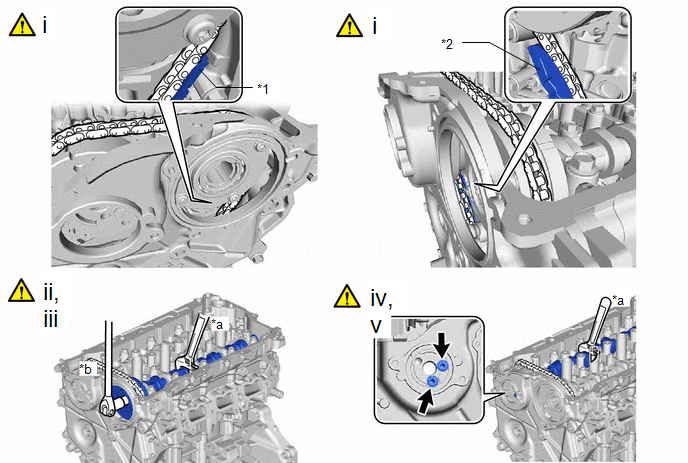

*1 | No. 1 Camshaft Bearing Cap |

*2 | No. 2 Camshaft Bearing Cap |

|

*3 | No. 3 Camshaft Bearing Cap |

*4 | No. 4 Camshaft Bearing Cap |

(1) Set the No. 1 camshaft bearing cap, No. 2 camshaft bearing cap, 2 No. 3 camshaft bearing caps and No. 4 camshaft bearing cap as shown in the illustration.

(2) Uniformly tighten the 13 bolts in the order shown in the illustration.

Torque:

28.5 N·m {291 kgf·cm, 21 ft·lbf}

(3) Uniformly tighten the 9 bolts in the order shown in the illustration.

Torque:

16 N·m {163 kgf·cm, 12 ft·lbf}

4. INSTALL CAMSHAFT TIMING GEAR ASSEMBLY

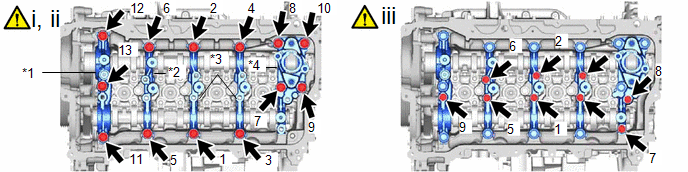

|

*a | Paint Mark |

*b | Timing Mark |

|

*c | Knock Pin |

- | - |

(1) Set the camshaft timing gear assembly and camshaft timing exhaust gear assembly to the chain sub-assembly as shown in the illustration.

(2) Align the timing mark on the camshaft timing gear assembly with the paint mark on the chain sub-assembly.

(3) Align the timing mark on the camshaft timing exhaust gear assembly with the paint mark on the chain sub-assembly.

(4) Using the hexagonal portion of the intake camshaft sub-assembly, install the camshaft timing gear assembly to the intake camshaft sub-assembly.

(5) Check that the knock pin matches the pin hole from the No. 2 timing chain cover assembly side.

(6) Using a 10 mm bi-hexagon socket wrench, temporarily install the camshaft timing gear assembly with the bolt.

HINT:

Temporarily install the bolt enough that the camshaft timing gear assembly does not detach from the knock pin of the intake camshaft sub-assembly.

(7) Using the hexagonal portion of the exhaust camshaft sub-assembly, install the camshaft timing exhaust gear assembly to the exhaust camshaft sub-assembly.

(8) Temporarily install with the 2 bolts.

HINT:

The 2 bolts can only be installed as shown in the illustration if the knock pin on the exhaust camshaft sub-assembly and the pin hole on the camshaft timing exhaust gear assembly match. If the 2 bolts cannot be installed, the knock pin and pin hole do not match.

|

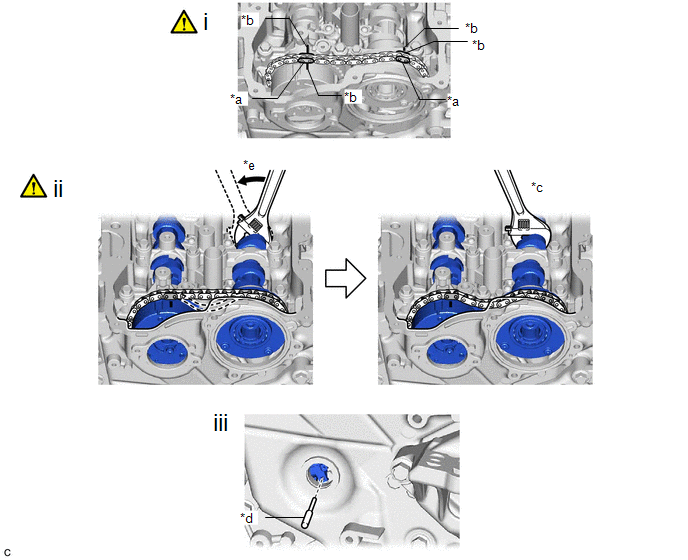

*1 | No. 1 Chain Vibration Damper |

*2 | Chain Tensioner Slipper |

|

*a | Hold |

*b | Turn |

(1) Check the status of the camshaft timing gear assembly and camshaft timing exhaust gear assembly temporarily installed to each camshaft.

1. Camshaft timing gear assembly side:

Check that the chain sub-assembly does not overlap the No. 1 chain vibration damper as shown in the illustration.

NOTICE:

If the chain sub-assembly overlaps the No. 1 chain vibration damper, install it again.

2. Camshaft timing exhaust gear assembly side:

Check that the chain sub-assembly does not overlap the chain tensioner slipper as shown in the illustration.

NOTICE:

If the chain sub-assembly overlaps the chain vibration slipper, install it again.

(2) Using the hexagonal portion of the intake camshaft sub-assembly, hold the intake camshaft sub-assembly.

NOTICE:

- Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

- Do not disassemble the camshaft timing gear assembly.

(3) Using a 10 mm bi-hexagon socket wrench, tighten the bolt on the camshaft timing gear assembly.

Torque:

86 N·m {877 kgf·cm, 63 ft·lbf}

(4) Using the hexagonal portion of the exhaust camshaft sub-assembly, hold the exhaust camshaft sub-assembly.

NOTICE:

- Do not damage the camshaft housing sub-assembly, cylinder head sub-assembly and spark plug tube.

- Do not disassemble the camshaft timing gear assembly.

(5) Using a 5 mm hexagon wrench, tighten the 2 bolts.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

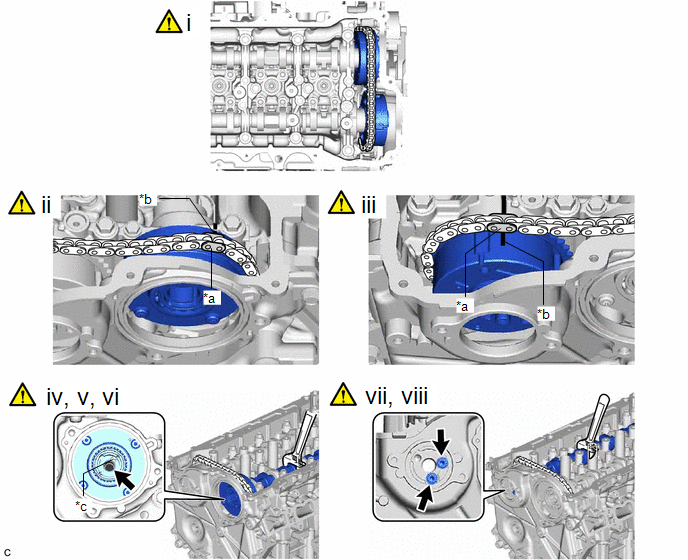

|

*a | Paint Mark |

*b | Timing Mark |

|

*c | Hold |

*d | Pin |

|

*e | Turn |

- | - |

(1) Check that the paint marks and timing marks are positioned as shown in the illustration.

(2) Using the hexagonal portion of the intake camshaft sub-assembly, check that the chain sub-assembly slackens when the intake camshaft sub-assembly is moved in the direction shown in the illustration.

NOTICE:

If the chain sub-assembly remains tight and does not slacken, the chain tensioner slipper and No. 1 chain vibration damper may overlap the chain sub-assembly, so install them again.

(3) Remove the pin from the No. 1 chain tensioner assembly.

5. INSTALL STRAIGHT SCREW PLUG

Click here .gif)

6. SET NO. 1 CYLINDER TO TDC (COMPRESSION)

Click here .gif)

7. INSTALL FUEL PUMP LIFTER GUIDE

Click here .gif)

8. INSTALL SPARK PLUG TUBE GASKET

Click here .gif)

9. TEMPORARILY INSTALL CAMSHAFT POSITION SENSOR

Click here .gif)

10. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

Click here .gif)

11. INSTALL CAM TIMING CONTROL MOTOR O-RING

Click here .gif)

12. INSTALL CAM TIMING CONTROL MOTOR WITH EDU ASSEMBLY

Click here .gif)

13. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (EXHAUST CAMSHAFT TIMING GEAR BOLT ASSEMBLY)

Click here .gif)

14. INSTALL IGNITION COIL ASSEMBLY

Click here .gif)

15. INSTALL VACUUM PUMP ASSEMBLY

Click here .gif)

16. INSTALL NO. 3 WATER HOSE CLAMP BRACKET

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

17. INSTALL VACUUM SURGE TANK

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

18. INSTALL ENGINE WIRE

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

19. CONNECT NO. 1 VACUUM HOSE CONNECTOR

.png) |

Click here |

20. INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

Click here

.gif)

.gif)

21. INSTALL ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

.png) |

Click here |

22. INSTALL NO. 1 COOLER REFRIGERANT HOSE

Click here

.gif)

23. INSTALL RADIATOR RESERVE TANK ASSEMBLY

Click here .gif)

24. REMOVE ENGINE SUPPORT BRIDGE

Click here .gif)