Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT POWER WINDOW REGULATOR MOTOR ASSEMBLY LH

(a) Check the operation.

|

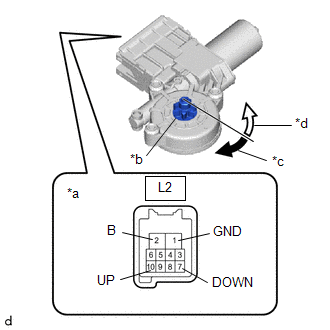

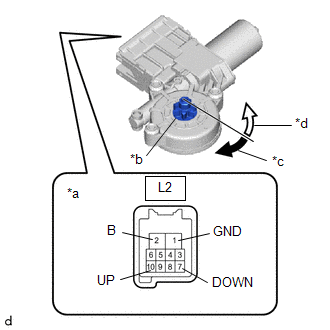

(1) Connect a positive (+) lead from the auxiliary battery to connector terminal L2-2 (B).

NOTICE: Do not connect a positive (+) lead from the auxiliary battery to any terminal other than terminal L2-2 (B) to avoid damaging the pulse sensor inside the motor. |

|

|

*a | Component without harness connected

(Power Window Regulator Motor Assembly LH) | |

*b | Motor Gear | |

*c | Clockwise | |

*d | Counterclockwise | | |

(2) Connect a negative (-) lead from the auxiliary battery to connector terminals L2-1 (GND) and L2-7 (DOWN) or L2-10 (UP).

(3) Check that the motor gear rotates smoothly as follows:

OK:

|

Measurement Condition | Specified Condition |

- Connect a positive (+) lead from the auxiliary battery to terminal L2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal L2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals L2-2 (B) and L2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal L2-10 (UP).

| Motor gear rotates clockwise |

- Connect a positive (+) lead from the auxiliary battery to terminal L2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal L2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals L2-2 (B) and L2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal L2-7 (DOWN).

| Motor gear rotates counterclockwise |

- If the result is not as specified, replace the power window regulator motor assembly LH.

CAUTION:

Initialize the power window control system after installing the front door window regulator assembly.

2. INSPECT POWER WINDOW REGULATOR MOTOR ASSEMBLY RH

(a) Check the operation.

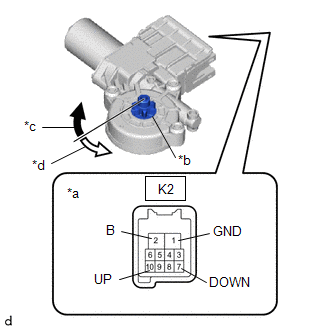

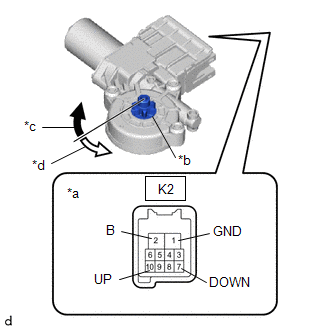

| (1) Connect a positive (+) lead from the auxiliary battery to connector terminal K2-2 (B).

NOTICE: Do not connect a positive (+) lead from the auxiliary battery to any terminal other than terminal K2-2 (B) to avoid damaging the pulse sensor inside the motor. |

|

|

*a | Component without harness connected

(Power Window Regulator Motor Assembly RH) | |

*b | Motor Gear | |

*c | Clockwise | |

*d | Counterclockwise | | |

(2) Connect a negative (-) lead from the auxiliary battery to connector terminals K2-1 (GND) and K2-7 (DOWN) or K2-10 (UP).

(3) Check that the motor gear rotates smoothly as follows:

OK:

|

Measurement Condition | Specified Condition |

- Connect a positive (+) lead from the auxiliary battery to terminal K2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal K2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals K2-2 (B) and K2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal K2-10 (UP).

| Motor gear rotates counterclockwise |

- Connect a positive (+) lead from the auxiliary battery to terminal K2-2 (B), connect a negative (-) lead from the auxiliary battery to terminal K2-1 (GND), and keep them connected for 3 seconds or more.

- With terminals K2-2 (B) and K2-1 (GND) connected, connect a negative (-) lead from the auxiliary battery to terminal K2-7 (DOWN).

| Motor gear rotates clockwise |

- If the result is not as specified, replace the power window regulator motor assembly RH.

CAUTION:

Initialize the power window control system after installing the front door window regulator assembly.

READ NEXT:

INSTALLATION CAUTION / NOTICE / HINT COMPONENTS (INSTALLATION)

Procedure Part Name Code

1 POWER WINDOW REGULATOR MOTOR ASSEMBLY

85720D

- -

2

REMOVAL CAUTION / NOTICE / HINT COMPONENTS (REMOVAL)

Procedure Part Name Code

1 REAR DOOR GLASS SUB-ASSEMBLY

68104

- -

2 REAR DOOR WINDOW

SEE MORE:

This section will introduce drivers and passengers to a plethora of features and conveniences that are designed to enhance comfort, convenience, and overall vehicle enjoyment.

This section looks at the interior, including how the seats are arranged and how to modify them for maximum comfort. To acc

REPLACEMENT

CAUTION / NOTICE / HINT

CAUTION:

To avoid the danger of being burned, do not remove the reserve tank cap or drain

cock plug while the coolant (for inverter) is still hot. Pressurized, hot coolant

(for inverter) and steam may be released and cause serious burns.

*1