Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

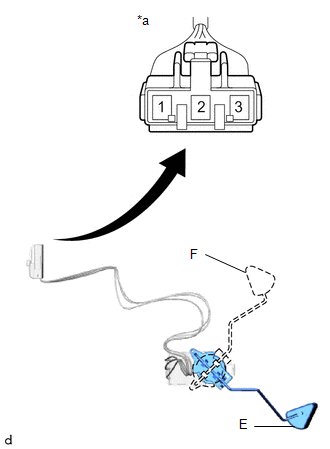

(a) Check that the float moves smoothly between F and E.

(b) Check the fuel sender gauge assembly voltage.

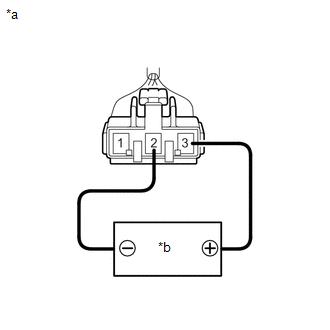

| (1) Apply 5 V between terminals 2 and 3. NOTICE:

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |

|

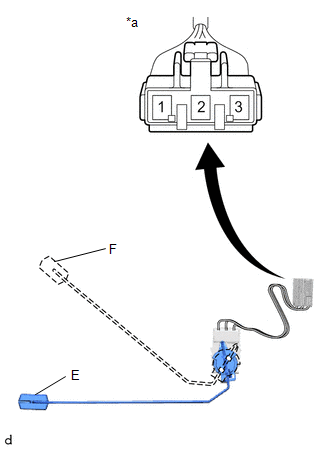

| (2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

*: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the fuel sender gauge assembly. |

|

2. INSPECT NO. 2 FUEL SENDER GAUGE ASSEMBLY

CAUTION:

Perform the inspection in a well-ventilated area.

Do not perform the inspection near an open flame.

(a) Check that the float moves smoothly between F and E.

(b) Check the No. 2 fuel sender gauge assembly voltage.

| (1) Apply 5 V between terminals 2 and 3. NOTICE:

HINT: If a stable power supply is not available, connect 4 nickel-metal hydride batteries (1.2 V each) or equivalent in series. |

|

| (2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

*: The output voltage changes depending on the voltage applied to the terminals. Output voltage (F) = (0.851 x Voltage applied to terminals) to (0.921 x Voltage applied to terminals) Output voltage (E) = (0.069 x Voltage applied to terminals) to (0.139 x Voltage applied to terminals) If the result is not as specified, replace the No. 2 fuel sender gauge assembly. |

|