Toyota Corolla Cross: Installation

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

|

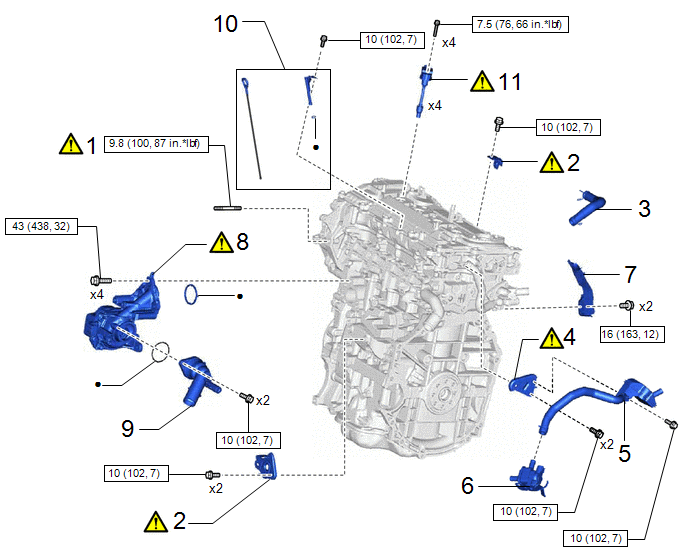

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

1 | STUD BOLT |

- |

|

- | - |

|

2 | WIRE HARNESS CLAMP BRACKET |

- |

|

- | - |

|

3 | NO. 2 VENTILATION HOSE |

12262 | - |

- | - |

|

4 | VACUUM SURGE TANK BRACKET |

25759A |

|

- | - |

|

5 | VACUUM SURGE TANK |

25719 | - |

- | - |

|

6 | PURGE VALVE (PURGE VSV) |

25860 | - |

- | - |

|

7 | NO. 3 EXHAUST MANIFOLD HEAT INSULATOR |

17169A | - |

- | - |

|

8 | ENGINE WATER PUMP ASSEMBLY (WATER INLET HOUSING) |

16032 |

|

- | - |

|

9 | WATER INLET WITH THERMOSTAT SUB-ASSEMBLY |

16031 | - |

- | - |

|

10 | ENGINE OIL LEVEL DIPSTICK GUIDE |

11452D | - |

- | - |

|

11 | IGNITION COIL ASSEMBLY |

19500 |

|

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

|

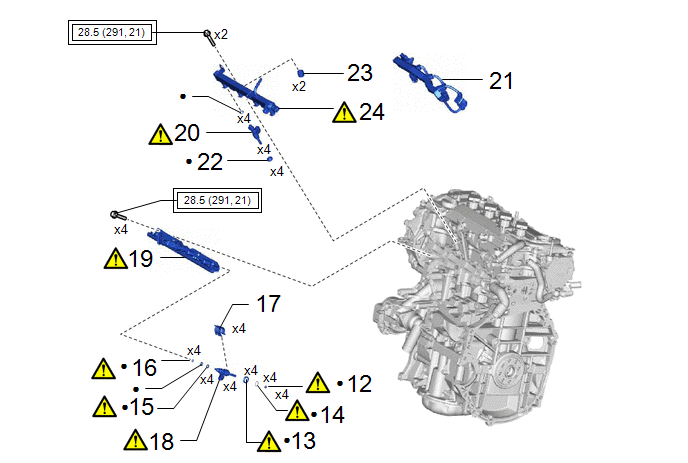

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

12 | FUEL INJECTOR SEAL |

23255A |

|

- | - |

|

13 | INJECTOR VIBRATION INSULATOR |

23291A |

|

- | - |

|

14 | C-RING |

- |

|

- | - |

|

15 | NO. 1 FUEL INJECTOR BACK-UP RING |

23256 |

|

- | - |

|

16 | NO. 3 FUEL INJECTOR BACK-UP RING |

23258 |

|

- | - |

|

17 | NOZZLE HOLDER CLAMP |

23695A |

- | - | |

|

18 | DIRECT FUEL INJECTOR ASSEMBLY |

23250E |

|

- | - |

|

19 | FUEL DELIVERY PIPE |

23814B |

|

- | - |

|

20 | PORT FUEL INJECTOR ASSEMBLY |

23250F |

|

- | - |

|

21 | NO. 5 ENGINE WIRE |

82125N | - |

- | - |

|

22 | INJECTOR VIBRATION INSULATOR |

23291 | - |

- | - |

|

23 | FUEL DELIVERY SPACER |

23891 | - |

- | - |

|

24 | FUEL DELIVERY PIPE SUB-ASSEMBLY |

23807 |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

● | Non-reusable part |

|

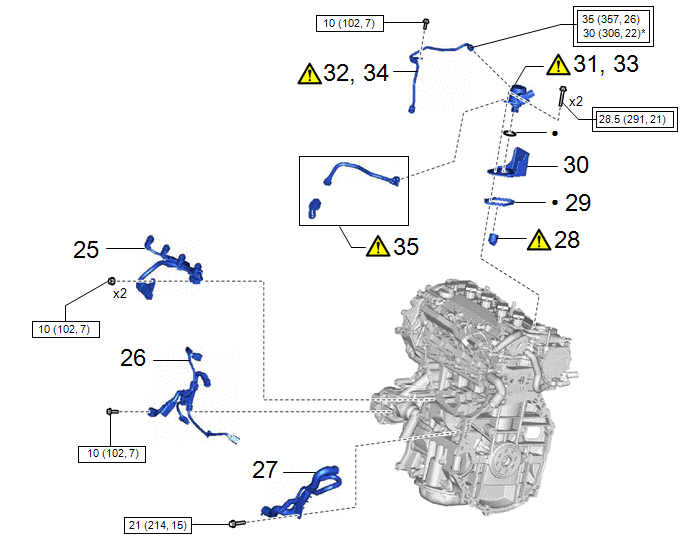

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

25 | NO. 6 ENGINE WIRE |

82126A | - |

- | - |

|

26 | SENSOR WIRE |

82219C | - |

- | - |

|

27 | NO. 1 WATER BY-PASS HOSE ASSEMBLY |

- | - |

- | - |

|

28 | FUEL PUMP LIFTER ASSY |

23470 |

|

- | - |

|

29 | FUEL PUMP SPACER GASKET |

23224D | - |

- | - |

|

30 | FUEL PUMP FLANGE |

23191 | - |

- | - |

|

31 | TEMPORARILY INSTALL FUEL(ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure) |

23100X |

|

- | - |

|

32 | TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY |

23801P |

|

- | - |

|

33 | INSTALL FUEL(ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure) |

23100X |

|

- | - |

|

34 | INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY |

23801P |

|

- | - |

|

35 | FUEL TUBE SUB-ASSEMBLY |

23910A |

|

- | - |

.png) |

Tightening torque for "Major areas involving basic vehicle performance such as moving/turning/stopping" : N*m (kgf*cm, ft.*lbf) |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

|

● | Non-reusable part |

* | For use with a union nut wrench |

|

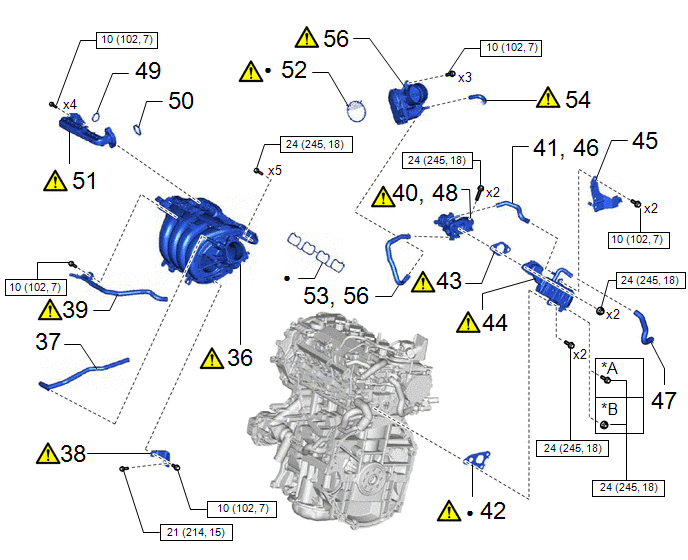

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

36 | INTAKE MANIFOLD |

17111 |

|

- | - |

|

37 | NO. 1 FUEL VAPOR FEED HOSE |

23826 | - |

- | - |

|

38 | INTAKE MANIFOLD STAY |

17138B |

|

- | - |

|

39 | INSTALL NO. 3 WATER BY-PASS PIPE |

16279 |

|

- | - |

|

40 | EGR VALVE ASSEMBLY |

25620 |

|

- | - |

|

41 | INSTALL NO. 4 WATER BY-PASS HOSE |

16281 | - |

- | - |

|

42 | NO. 1 EGR COOLER GASKET |

25685 |

|

- | - |

|

43 | EGR VALVE GASKET |

25627 |

|

- | - |

|

44 | EGR COOLER ASSEMBLY |

25680 |

|

- | - |

|

45 | WIRE HARNESS CLAMP BRACKET |

- | - |

- | - |

|

46 | CONNECT NO. 4 WATER BY-PASS HOSE |

16281 | - |

- | - |

|

47 | CONNECT NO. 3 WATER BY-PASS HOSE |

16267 | - |

- | - |

|

48 | EGR VALVE ASSEMBLY |

25620 |

|

- | - |

|

49 | EGR INLET GASKET |

25628 | - |

- | - |

|

50 | EGR VALVE ADAPTER GASKET |

25629 | - |

- | - |

|

51 | NO. 1 EGR PIPE SUB-ASSEMBLY |

25601 |

|

- | - |

|

52 | THROTTLE BODY GASKET |

22271 |

|

- | - |

|

53 | CONNECT NO. 8 WATER BY-PASS HOSE |

16296 | - |

- | - |

|

54 | CONNECT NO. 5 WATER BY-PASS HOSE |

16282 |

|

- | - |

|

55 | THROTTLE BODY WITH MOTOR ASSEMBLY |

22030 | - |

- | - |

|

56 | INSTALL NO. 8 WATER BY-PASS HOSE |

16296 |

|

- | - |

|

*A | Type A |

*B | Type B |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

|

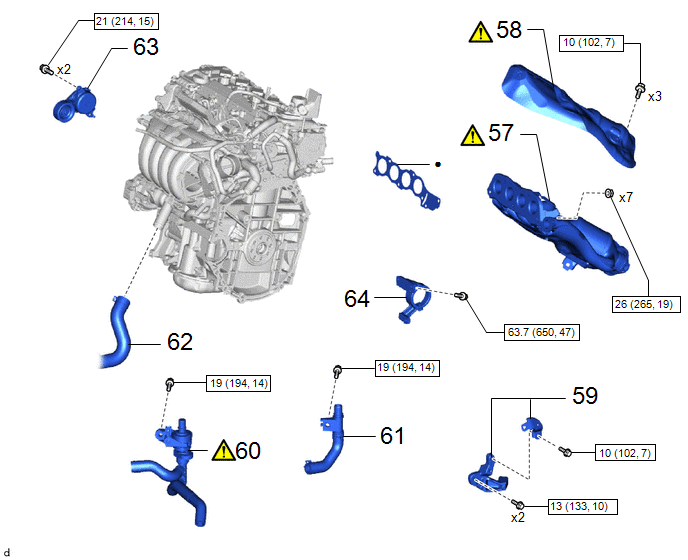

Procedure | Part Name Code |

.png) |

.png) |

.png) | |

|---|---|---|---|---|---|

|

57 | EXHAUST MANIFOLD (TWC: Front Catalyst) |

17141 |

|

- | - |

|

58 | NO. 1 EXHAUST MANIFOLD HEAT INSULATOR |

17167 |

|

- | - |

|

59 | WATER HOSE CLAMP BRACKET |

16575B | - |

- | - |

|

60 | FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY) |

16260 | - |

- | - |

|

61 | NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY |

16207 |

|

- | - |

|

62 | NO. 2 RADIATOR HOSE |

16572D | - |

- | - |

|

63 | V-RIBBED BELT TENSIONER ASSEMBLY |

16620D | - |

- | - |

|

64 | DRIVE SHAFT BEARING BRACKET |

43457 | - |

- | - |

.png) |

N*m (kgf*cm, ft.*lbf): Specified torque |

● | Non-reusable part |

CAUTION / NOTICE / HINT

NOTICE:

This procedure includes the installation of small-head bolts. Refer to Small-Head Bolts of Basic Repair Hint to identify the small-head bolts.

Click here .gif)

.gif)

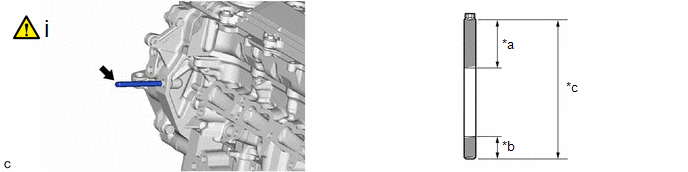

PROCEDURE

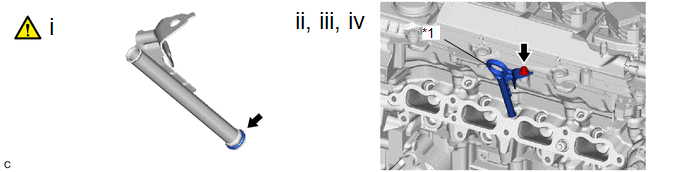

1. INSTALL STUD BOLT

|

*a | 33.1 mm (1.30 in.) |

*b | 15 mm (0.591 in.) |

|

*c | 95 mm (3.74 in.) |

- | - |

(1) Using an E8 "TORX" socket wrench, install the stud bolt to the timing chain cover assembly.

Torque:

9.8 N·m {100 kgf·cm, 87 in·lbf}

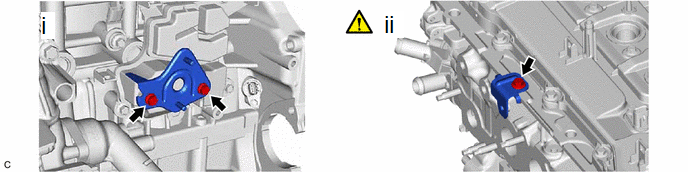

2. INSTALL WIRE HARNESS CLAMP BRACKET

(1) Install the wire harness clamp bracket to the camshaft housing sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(2) Using an 8 mm socket wrench, install the wire harness clamp bracket to the No. 1 ventilation case with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

3. INSTALL NO. 2 VENTILATION HOSE

4. INSTALL VACUUM SURGE TANK BRACKET

(1) Using an 8 mm socket wrench, install the vacuum surge tank bracket to the camshaft housing sub-assembly with the 2 bolts.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

5. INSTALL VACUUM SURGE TANK

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

6. INSTALL PURGE VALVE (PURGE VSV)

Click here .gif)

7. INSTALL NO. 3 EXHAUST MANIFOLD HEAT INSULATOR

Torque:

16 N·m {163 kgf·cm, 12 ft·lbf}

8. INSTALL ENGINE WATER PUMP ASSEMBLY (WATER INLET HOUSING)

.png) |

Click here |

9. INSTALL WATER INLET WITH THERMOSTAT SUB-ASSEMBLY

Click here

.gif)

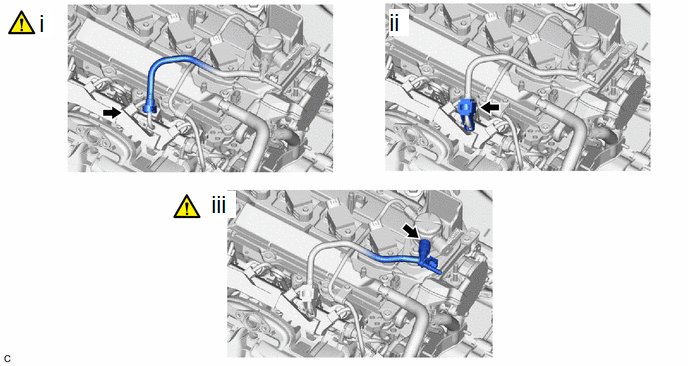

10. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

|

*1 | OIL LEVEL GAGE SUB-ASSEMBLY |

- | - |

(1) Apply a light coat of engine oil to a new O-ring.

(2) Install the O-ring to the engine oil level dipstick guide.

(3) Using an 8 mm socket wrench, install the engine oil level dipstick guide to the cylinder head sub-assembly with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

(4) Install the engine oil level dipstick.

11. INSTALL IGNITION COIL ASSEMBLY

.png) |

Click here |

12. INSTALL FUEL INJECTOR SEAL

.png) |

Click here |

13. INSTALL INJECTOR VIBRATION INSULATOR

.png) |

Click here |

14. INSTALL C-RING

.png) |

Click here |

15. INSTALL NO. 1 FUEL INJECTOR BACK-UP RING

.png) |

Click here |

16. INSTALL NO. 3 FUEL INJECTOR BACK-UP RING

.png) |

Click here |

17. INSTALL NOZZLE HOLDER CLAMP

Click here

.gif)

18. INSTALL DIRECT FUEL INJECTOR ASSEMBLY

.png) |

Click here |

19. INSTALL FUEL DELIVERY PIPE

.png) |

Click here |

20. INSTALL PORT FUEL INJECTOR ASSEMBLY

.png) |

Click here |

21. INSTALL NO. 5 ENGINE WIRE

Click here

.gif)

22. INSTALL INJECTOR VIBRATION INSULATOR

.png) |

Click here |

23. INSTALL FUEL DELIVERY SPACER

Click here

.gif)

24. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

.png) |

Click here |

25. INSTALL NO. 6 ENGINE WIRE

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

26. INSTALL SENSOR WIRE

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

27. INSTALL NO. 1 WATER BY-PASS HOSE ASSEMBLY

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

28. INSTALL FUEL PUMP LIFTER ASSY

29. INSTALL FUEL PUMP SPACER GASKET

30. INSTALL FUEL PUMP FLANGE

31. TEMPORARILY INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

.png) |

Click here |

32. TEMPORARILY INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

.png) |

Click here |

33. INSTALL FUEL (ENGINE ROOM SIDE) PUMP ASSEMBLY (for High Pressure)

.png) |

Click here |

34. INSTALL NO. 1 FUEL PIPE SUB-ASSEMBLY

.png) |

Click here |

35. CONNECT FUEL TUBE SUB-ASSEMBLY

(1) Connect the fuel tube sub-assembly to the fuel delivery pipe sub-assembly.

(2) Install the fuel pipe clamp to the fuel tube connector.

(3) Connect the fuel tube sub-assembly to the fuel pump assembly.

36. INSTALL INTAKE MANIFOLD

.png) |

Click here |

37. CONNECT NO. 1 FUEL VAPOR FEED HOSE

Click here

.gif)

38. INSTALL INTAKE MANIFOLD STAY

.png) |

Click here |

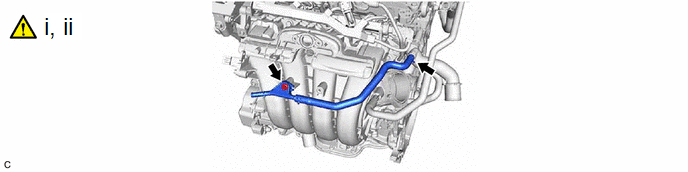

39. INSTALL NO. 3 WATER BY-PASS PIPE

(1) Install the No. 3 water by-pass pipe to the water outlet and slide the clip to secure it.

(2) Using an 8 mm socket wrench, connect the No. 3 water by-pass pipe to the intake manifold with the bolt.

Torque:

10 N·m {102 kgf·cm, 7 ft·lbf}

40. SET EGR VALVE ASSEMBLY

Click here .gif)

41. INSTALL NO. 4 WATER BY-PASS HOSE

42. INSTALL NO. 1 EGR COOLER GASKET

.png) |

|

43. INSTALL EGR VALVE GASKET

Click here .gif)

44. INSTALL EGR COOLER ASSEMBLY

.png) |

Click here |

45. INSTALL WIRE HARNESS CLAMP BRACKET

Click here

.gif)

46. CONNECT NO. 4 WATER BY-PASS HOSE

47. CONNECT NO. 3 WATER BY-PASS HOSE

48. INSTALL EGR VALVE ASSEMBLY

.png) |

Click here |

49. INSTALL EGR INLET GASKET

Click here

.gif)

50. INSTALL EGR VALVE ADAPTER GASKET

Click here .gif)

51. INSTALL NO. 1 EGR PIPE SUB-ASSEMBLY

Click here .gif)

52. INSTALL THROTTLE BODY GASKET

.png) |

|

53. CONNECT NO. 8 WATER BY-PASS HOSE

Click here .gif)

54. CONNECT NO. 5 WATER BY-PASS HOSE

.png) |

Click here |

55. INSTALL THROTTLE BODY WITH MOTOR ASSEMBLY

.png) |

Click here |

56. INSTALL NO. 8 WATER BY-PASS HOSE

.png) |

Click here |

57. INSTALL EXHAUST MANIFOLD (TWC: Front Catalyst)

.png) |

|

58. INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

- for 2WD:

Click here

.gif)

- for AWD:

Click here

.gif)

59. INSTALL WATER HOSE CLAMP BRACKET

Torque:

13 N·m {133 kgf·cm, 10 ft·lbf}

60. INSTALL FLOW SHUTTING VALVE (WATER BY-PASS HOSE ASSEMBLY)

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

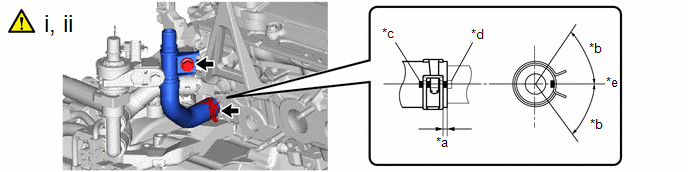

61. INSTALL NO. 2 WATER BY-PASS PIPE SUB-ASSEMBLY

|

*a | 2 to 13 mm (0.0787 to 0.5118 in.) |

*b | 60° |

|

*c | Paint Mark |

*d | Protrusion |

|

*e | RH Side of Vehicle |

- | - |

(1) Install the No. 2 water by-pass pipe sub-assembly to the water hose clamp bracket with the bolt.

Torque:

19 N·m {194 kgf·cm, 14 ft·lbf}

(2) Connect the No. 2 water by-pass pipe sub-assembly to the water by-pass outlet sub-assembly and slide the clip to secure it.

NOTICE:

- Make sure to slide the No. 2 water by-pass pipe sub-assembly until it contacts the hose stopper of the water by-pass outlet sub-assembly.

- Make sure that the claws of the clip are within the location shown in the illustration.

62. INSTALL NO. 2 RADIATOR HOSE

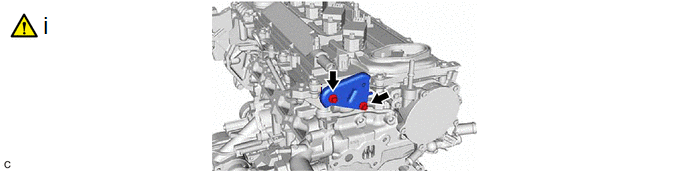

63. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

.png) |

NOTICE:

.png) |

Torque:

21 N·m {214 kgf·cm, 15 ft·lbf}

64. INSTALL DRIVE SHAFT BEARING BRACKET (for AWD)

Torque:

63.7 N·m {650 kgf·cm, 47 ft·lbf}