Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT SHIFT LEVER POSITION SENSOR

|

(a) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection

|

Condition

|

Specified Condition

|

|

7 (+B) - 3 (PR)

|

Shift lever in P

|

Below 1 Ω

|

|

7 (+B) - 4 (PNB)

|

Below 1 Ω

|

|

7 (+B) - 8 (P)

|

Below 1 Ω

|

|

7 (+B) - 1 (DB1), 2 (N), 6 (DB2) or 9 (R)

|

Shift lever in P

|

10 kΩ or higher

|

|

7 (+B) - 3 (PR)

|

Shift lever in R

|

Below 1 Ω

|

|

7 (+B) - 9 (R)

|

Below 1 Ω

|

|

7 (+B) - 1 (DB1), 2 (N), 4 (PNB), 6 (DB2) or 8 (P)

|

Shift lever in R

|

10 kΩ or higher

|

|

7 (+B) - 2 (N)

|

Shift lever in N

|

Below 1 Ω

|

|

7 (+B) - 4 (PNB)

|

Below 1 Ω

|

|

7 (+B) - 1 (DB1), 3 (PR), 6 (DB2), 8 (P) or 9 (R)

|

Shift lever in N

|

10 kΩ or higher

|

|

7 (+B) - 1 (DB1)

|

Shift lever in D

|

Below 1 Ω

|

|

7 (+B) - 6 (DB2)

|

Below 1 Ω

|

|

7 (+B) - 2 (N), 3 (PR), 4 (PNB), 8 (P) or 9 (R)

|

Shift lever in D

|

10 kΩ or higher

|

|

7 (+B) - 1 (DB1)

|

Shift lever in B

|

Below 1 Ω

|

|

7 (+B) - 4 (PNB)

|

Below 1 Ω

|

|

7 (+B) - 6 (DB2)

|

Below 1 Ω

|

|

7 (+B) - 2 (N), 3 (PR), 8 (P) or 9 (R)

|

Shift lever in B

|

10 kΩ or higher

|

HINT:

The shift lever position sensor connector (shift lever position sensor

side) does not have a terminal 5.

If the result is not as specified, replace the shift lever position sensor.

|

|

|

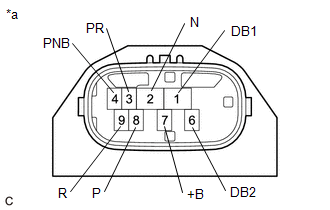

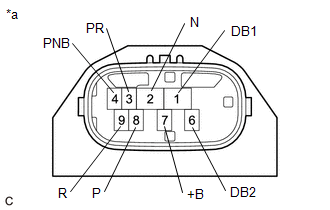

*a

|

Component without harness connected

(Shift Lever Position Sensor)

|

|

|

READ NEXT:

ADJUSTMENT

PROCEDURE

1. SECURE VEHICLE

(a) Fully apply the parking brake and chock a wheel.

CAUTION:

Make sure to apply the parking brake and chock a wheel before performing

this procedure.

INSTALLATION

CAUTION / NOTICE / HINT

COMPONENTS (INSTALLATION)

Procedure

Part Name Code

1

SHIFT LEVER POSITION SENSOR S

SEE MORE:

DESCRIPTION The ECM calculates and compares the accelerator pedal opening angle value used for control and the value used for monitoring.

DTC No. Detection Item

DTC Detection Condition Trouble Area

MIL Note

P060694 Control Module Processor Unexpected Operation

C

DESCRIPTION The HV battery is composed of 60 cells (3.7 V each) in series. The battery ECU assembly monitors the capacity of each HV battery cell to detect malfunctions of the HV battery.

DTC No. Detection Item

DTC Detection Condition

Trouble Area MIL

Warning Indicate