Toyota Corolla Cross: Generator High-voltage Circuit

DESCRIPTION

The cause of this malfunction may be the generator high-voltage circuit.

Check the generator internal resistance and the connection condition of the high-voltage line between the inverter and generator to check whether there is an open or short circuit.

Related Parts Check|

Area | Inspection |

|---|---|

|

Motor cable (for MG1) connection check |

Check for the connection condition of the cable from the inverter to the generator. |

|

Generator or motor cable (for MG1) |

Check the generator (including cable) internal resistance and the insulation resistance with body ground to check for an open or short circuit. |

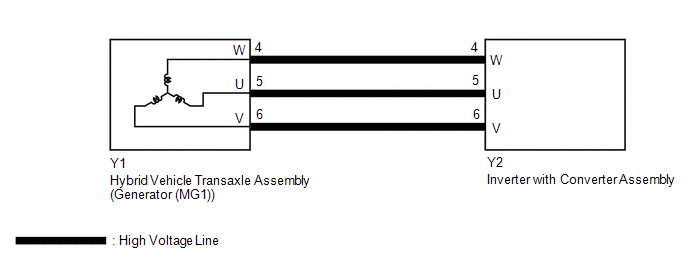

WIRING DIAGRAM

CAUTION / NOTICE / HINT

This diagnostic procedure is referenced to in the diagnostic procedure of several DTCs.

If the result of this diagnostic procedure is normal, proceed as directed in the procedure for the DTC.

CAUTION:

Refer to the precautions before inspecting high voltage circuit.

Click here .gif)

NOTICE:

- After the ignition switch is turned off, there may be a waiting time before disconnecting the negative (-) auxiliary battery terminal.

Click here

.gif)

- When disconnecting and reconnecting the auxiliary battery

HINT:

When disconnecting and reconnecting the auxiliary battery, there is an automatic learning function that completes learning when the respective system is used.

Click here

.gif)

PROCEDURE

|

1. | CHECK INVERTER WITH CONVERTER ASSEMBLY (MOTOR CABLE CONNECTION CONDITION) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the inverter cover from the inverter with converter assembly.

| (c) Check that the bolts for the motor cable are tightened to the specified torque, the generator cable is connected securely, and there are no contact problems. Specified Condition: T = 8.0 N*m (82 kgf*cm, 71 in.*lbf) |

|

(d) Disconnect the motor cable from the inverter with converter assembly.

(e) Check for arc marks at the terminals for the motor cable.

|

Result | Proceed to | |

|---|---|---|

|

The terminals are connected securely and there are no contact problems. |

There are no arc marks. |

A |

| The terminals are not connected securely and there is a contact problem. |

There are arc marks. |

B |

| The terminals are not connected securely and there is a contact problem. |

There are no arc marks. |

C |

| The terminals are connected securely and there are no contact problems. |

There are arc marks. |

B |

(f) Reconnect the motor cable.

(g) Reinstall the inverter cover.

| B | .gif) | REPLACE MALFUNCTIONING PARTS |

| C | .gif) | CONNECT SECURELY |

|

|

2. | CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (GENERATOR (MG1)) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the inverter cover from the inverter with converter assembly.

(c) Disconnect the motor cable from the inverter with converter assembly.

| (d) Using a milliohmmeter, measure the resistance according to the value(s) in the table below. HINT: If the generator (MG1) temperature is high, the resistance will vary greatly from the specification. Therefore, measure the resistance at least 8 hours after the vehicle is stopped. Standard Resistance:

HINT: To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68°F). R20 = Rt / {1 + 0.00393 X (T - 20)} The calculation is based on the following: R20: Resistance at 20°C (68°F) (mΩ) Rt: Measured resistance (mΩ) T: Temperature when the resistance is measured (°C) |

|

(e) Check the difference in measured resistance values according to the table below.

Standard:

|

Inspection Item | Specified Condition |

|---|---|

|

[*1] - [*2] | -1.2 to 1.0 mΩ |

|

[*2] - [*3] | -1.2 to 0.9 mΩ |

|

[*3] - [*1] | -0.8 to 1.3 mΩ |

(f) Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

NOTICE:

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

Y2-4 (W) - Body ground and shield ground |

Ignition switch off |

100 MΩ or higher |

|

Y2-5 (U) - Body ground and shield ground |

Ignition switch off |

100 MΩ or higher |

|

Y2-6 (V) - Body ground and shield ground |

Ignition switch off |

100 MΩ or higher |

(g) Reconnect the motor cable.

(h) Reinstall the inverter cover.

| OK | .gif) | GENERATOR HIGH-VOLTAGE CIRCUIT NORMAL (PERFORM NEXT STEP FOR REFERENCED DTC) |

|

|

3. | CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MOTOR CABLE CONNECTION CONDITION) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the inverter with converter assembly.

| (c) Check that the bolts for the motor cable are tightened to the specified torque, the motor cable is connected securely, and there are no contact problems. Specified Condition: T=10 N*m (102 kgf*cm, 7 ft.*lbf) |

|

(d) Disconnect the motor cable from the hybrid vehicle transaxle assembly.

(e) Check for arc marks at the terminals for the generator cable.

|

Result | Proceed to | |

|---|---|---|

|

The terminals are connected securely and there are no contact problems. |

There are no arc marks. |

A |

| The terminals are not connected securely and there is a contact problem. |

There are arc marks. |

B |

| The terminals are not connected securely and there is a contact problem. |

There are no arc marks. |

C |

| The terminals are connected securely and there are no contact problems. |

There are arc marks. |

B |

(f) Reconnect the motor cable.

(g) Reinstall the inverter with converter assembly.

| B | .gif) | REPLACE MALFUNCTIONING PARTS |

| C | .gif) | CONNECT SECURELY |

|

|

4. | CHECK MOTOR CABLE (FOR MG1) |

CAUTION:

Be sure to wear insulated gloves.

(a) Check that the service plug grip is not installed.

NOTICE:

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

(b) Remove the inverter with converter assembly.

(c) Remove the motor cable.

(d) Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

|

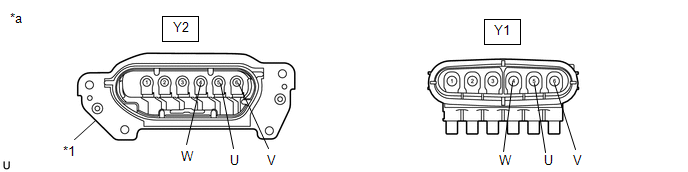

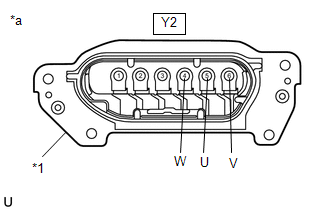

*1 | Shield Ground |

- | - |

|

*a | Motor Cable |

- | - |

NOTICE:

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

Y2-4 (W) or Y1-4 (W) - Shield ground |

Ignition switch off |

100 MΩ or higher |

|

Y2-5 (U) or Y1-5 (U) - Shield ground |

Ignition switch off |

100 MΩ or higher |

|

Y2-6 (V) or Y1-6 (V) - Shield ground |

Ignition switch off |

100 MΩ or higher |

NOTICE:

Wrap the terminals of the motor cable with insulating tape to prevent them from coming into contact with body ground.

(e) Measure the resistance according to the value(s) in the table below.

Standard Resistance:

|

Tester Connection | Condition |

Specified Condition |

|---|---|---|

|

Y2-4 (W) - Y1-4 (W) |

Ignition switch off |

Below 1 Ω |

|

Y2-5 (U) - Y1-5 (U) |

Ignition switch off |

Below 1 Ω |

|

Y2-6 (V) - Y1-6 (V) |

Ignition switch off |

Below 1 Ω |

|

Y2-4 (W) - Y1-5 (U) |

Ignition switch off |

100 MΩ or higher |

|

Y2-5 (U) - Y1-6 (V) |

Ignition switch off |

100 MΩ or higher |

|

Y2-6 (V) - Y1-4 (W) |

Ignition switch off |

100 MΩ or higher |

(f) Reinstall the motor cable.

(g) Reinstall the inverter with converter assembly.

| OK | .gif) | REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY |

| NG | .gif) | REPLACE MOTOR CABLE |

.png)

.gif)

.png)