Toyota Corolla Cross: Transmission Fluid Pressure Sensor/Switch "A" Circuit Range/Performance (P084000,P28287F)

DESCRIPTION

The TCM controls the secondary oil pressure based on the secondary oil pressure signal output by the oil pressure sensor.

|

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

Note |

|---|---|---|---|---|---|---|

|

P084000 |

Transmission Fluid Pressure Sensor/Switch "A" Circuit Range/Performance |

Either of the following conditions is met (1-trip detection logic):

|

|

Comes on |

DTC stored |

SAE Code: P0841 |

|

P28287F |

Pressure Control Solenoid "K" Actuator Stuck Off |

Either of the following conditions is met (1-trip detection logic):

|

|

Comes on |

DTC stored |

SAE Code: P2829 |

MONITOR DESCRIPTION

The TCM checks for belt clamping high-pressure or low-pressure malfunctions. If a mechanical malfunction of the shift solenoid valve SLS or a malfunction of the oil pressure sensor is detected by the TCM, it illuminates the MIL and stores a DTC.

MONITOR STRATEGY

|

Related DTCs |

P0841: Transmission fluid pressure sensor "A" (PTO (Oil pressure sensor))/Rationality fault diagnostics P2829: Pressure control solenoid "K" (Shift solenoid valve SLS)/Functional check |

|

Required sensors/Components |

Crankshaft position sensor Transmission revolution sensor (NT) Transmission revolution sensor (NC1) Transmission revolution sensor (NSS) Transmission revolution sensor (NOUT) CVT fluid temperature sensor Engine coolant temperature sensor Oil pressure sensor Shift solenoid valve SL1 Shift solenoid valve SL2 Shift solenoid valve SLP Shift solenoid valve SLS Shift solenoid valve SLU |

|

Frequency of operation |

Continuous |

|

Duration |

P0841:

|

|

MIL operation |

1 driving cycle |

|

Sequence of operation |

None |

TYPICAL ENABLING CONDITIONS

All|

ETC system (Electronic throttle control system) |

Not system down (MIL illuminated by following codes: P0121, P0122, P0123, P0222, P0223, P0604, P0606, P0607, P060D, P060E, P0657, P0658, P1607, P16B0, P2102, P2103, P2111, P2112, P2119, P2135) |

|

KCS sensor circuit (Knock sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0327, P0328) |

|

ECT sensor circuit (Engine coolant temperature sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0117, P0118) |

|

IAT sensor circuit (Intake air temperature sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0112, P0113) |

|

Crankshaft position sensor "A" circuit (Crankshaft position sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0335, P0337, P0338) |

|

CAN communication between ECM and TCM |

Not system down (MIL illuminated by following codes: U0100, U0101) |

|

Low voltage flag |

OFF |

|

Transmission fluid pressure sensor "A" circuit (Oil pressure sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0842, P0843) |

|

Pressure control solenoid "J" circuit (Shift solenoid valve SLP) |

Not circuit malfunction (MIL illuminated by following codes: P2826, P2827) |

|

Pressure control solenoid "K" circuit (Shift solenoid valve SLS) |

Not circuit malfunction (MIL illuminated by following codes: P282F, P2830) |

|

Torque converter clutch pressure control solenoid circuit (Shift solenoid valve SLU) |

Not circuit malfunction (MIL illuminated by following codes: P2763, P2764) |

|

Pressure control solenoid "A" circuit (Shift solenoid valve SL1) |

Not circuit malfunction (MIL illuminated by following codes: P0962, P0963) |

|

Pressure control solenoid "B" circuit (Shift solenoid valve SL2) |

Not circuit malfunction (MIL illuminated by following codes: P0966, P0967) |

|

Transmission fluid temperature sensor "A" circuit (CVT fluid temperature sensor) |

Not circuit malfunction (MIL illuminated by following codes: P0712, P0713) |

|

Turbine speed sensor "A" circuit (Transmission revolution sensor (NT)) |

Not circuit malfunction (MIL illuminated by following codes: P0717, P07BF, P07C0) |

|

Intermediate shaft speed sensor "C" circuit (Transmission revolution sensor (NSS)) |

Not circuit malfunction (MIL illuminated by following codes: P07C9, P07CA, P2751) |

|

Output speed sensor circuit (Transmission revolution sensor (NOUT)) |

Not circuit malfunction (MIL illuminated by following codes: P0722, P077C, P077D) |

|

Intermediate shaft speed sensor "B" circuit (Transmission revolution sensor (NC1)) |

Not circuit malfunction (MIL illuminated by following codes: P07C7, P07C8, P2747) |

- OFF malfunction (A)

OFF malfunction (B)Engine speed

550 rpm or more

Transmission fluid temperature

-10°C (14°F) or more

Time after following condition is met

0.5 sec. or more

- l Variation of the accelerator pedal angle l

(within 32.768 msec.)

Less than 0.5%

Shift solenoid valve SLS

Operating clamping pressure control by TCM command

ECT

60°C (140°F) or more

Spark advance from MAX. retard timing by KCS control

0°CA or more

Gear and belt mode clutch

Either engagement or disengagement

OFF malfunction (C)Shift solenoid valve SLP

Operating shift control by TCM command

Engine speed

500 rpm or more

Synchronizer

Engaged

Turbine speed

More than 0 rpm

Any of the following conditions are met: (a) or (b)

-

(a) Gear mode clutch speed

More than 0 rpm

(b) All of the following conditions are met

-

- Gear mode clutch speed

0 rpm

- Output speed

0 rpm

OFF malfunction (D)Shift position

"N" or "P" or "D" or "B"

Gear shift position circuit

Not circuit malfunction

(P0916, P0917)

Shift solenoid valve SLP

Operating shift control by TCM command

Engine speed

500 rpm or more

ON malfunction (A)Any of the following conditions are met: (a) or (b)

-

(a) Gear mode clutch

Engaged

(b) Belt mode clutch

Engaged

Engine speed

1000 rpm or more

Shift solenoid valve SLP

Operating shift control by TCM command

ON malfunction (B)Engine speed

550 rpm or more

Transmission fluid temperature

-10°C (14°F) or more

Time after following condition is met

0.5 sec. or more

- l Variation of the accelerator pedal angle l

(within 32.768 msec.)

Less than 0.5%

Shift solenoid valve SLS

Operating clamping pressure control by TCM command

ECT

60°C (140°F) or more

Spark advance from MAX. retard timing by KCS control

0°CA or more

All of the following conditions are met

-

- Gear mode clutch

Engaged

- Belt mode clutch

Engaged

Tire

Not slipping

Primary sheave speed

100 rpm or more

Secondary sheave speed

150 rpm or more

Output speed

1000 rpm or more

Transmission fluid temperature

-10°C (14°F) or more and less than 140°C (284°F)

Belt mode clutch

Engaged

Shift solenoid valve SLP

Operating shift control by TCM command

Actual gear ratio

More than 0.5 and 2.2 or less

Accelerator pedal

ON

Target clamping pressure

Less than 1.0 MPa (10.2 kgf/cm2, 145 psi)

Target gear ratio

More than 0.9 and 1.1 or less

- All

OFF malfunction (A)Engine speed

550 rpm or more

Transmission fluid temperature

-10°C (14°F) or more

Time after following condition is met

0.5 sec. or more

- l Variation of the accelerator pedal angle l

(within 32.768 msec.)

Less than 0.5%

Shift solenoid valve SLS

Operating clamping pressure control by TCM command

ECT

60°C (140°F) or more

Spark advance from MAX. retard timing by KCS control

0°CA or more

OFF malfunction (B)Any of the following conditions are met: (a) or (b)

-

(a) Gear mode clutch

Engaged

(b) Belt mode clutch

Engaged

ON malfunctionTire

Not slipping

Primary sheave speed

100 rpm or more

Secondary sheave speed

150 rpm or more

Output speed

1000 rpm or more

Transmission fluid temperature

-10°C (14°F) or more and less than 140°C (284°F)

Belt mode clutch

Engaged

Shift solenoid valve SLP

Operating shift control by TCM command

Actual gear ratio

More than 0.5 and 2.2 or less

Accelerator pedal

ON

Target clamping pressure

Less than 1.0 MPa (10.2 kgf/cm2, 145 psi)

Target gear ratio

More than 0.9 and 1.1 or less

Gear and belt mode clutch

Either engagement or disengagement

TYPICAL MALFUNCTION THRESHOLDS

P0841:- OFF malfunction

- OFF malfunction (A) is met and none of the following conditions are

met: OFF malfunction (B), (C) and (D) OFF malfunction (A)

OFF malfunction (B)Target clamping pressure

1.4 MPa (14.3 kgf/cm2, 203 psi) or more

Actual clamping pressure

Less than 0.5 MPa (5.1 kgf/cm2, 73 psi)

OFF malfunction (C)TCM indicate gear mode clutch

Engagement

l Turbine Speed - Gear mode clutch speed l

More than 200 rpm

OFF malfunction (D)TCM indicate synchronizer

Engagement

Synchronizer

Not engaged

TCM indicate lock-up clutch

Engagement

l Engine speed - Turbine speed l

250 rpm or more

- OFF malfunction (A) is met and none of the following conditions are

met: OFF malfunction (B), (C) and (D) OFF malfunction (A)

- ON malfunction

- All of the following conditions are met ON malfunction (A)

ON malfunction (B) (after ON malfunction (A) is met)Target clamping pressure

Less than 1.0 MPa (10.2 kgf/cm2, 145 psi)

Actual clamping pressure

2.5 MPa (25.5 kgf/cm2, 363 psi) or more

*: Calculated primary pulley pressure is calculated by value of transmission fluid pressure sensor "A" (oil pressure sensor) and actual gear ratio. Calculated primary pulley pressure* - Target primary pulley pressure

2.0 MPa (20.4 kgf/cm2, 290 psi) or more

- All of the following conditions are met ON malfunction (A)

- OFF malfunction

- All of the following conditions are met OFF malfunction (A)

OFF malfunction (B) (after OFF malfunction (A) is met)Target clamping pressure

Less than 1.0 MPa (10.2 kgf/cm2, 145 psi)

Actual clamping pressure

2.5 MPa (25.5 kgf/cm2, 363 psi) or more

*: Calculated primary pulley pressure is calculated by value of transmission fluid pressure sensor "A" (oil pressure sensor) and actual gear ratio. Calculated primary pulley pressure* - Target primary pulley pressure

Less than 0.5 MPa (5.1 kgf/cm2, 73 psi)

- All of the following conditions are met OFF malfunction (A)

- ON malfunction

Target clamping pressure

1.4 MPa (14.3 kgf/cm2, 203 psi) or more

Actual clamping pressure

Less than 0.5 MPa (5.1 kgf/cm2, 73 psi)

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

HINT:

- After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

- When clearing the permanent DTCs, refer to the Clear Permanent DTC procedure.

Click here

.gif)

.gif)

- Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

- Turn the ignition switch off and wait for 2 minutes or more.

- Turn the ignition switch to ON and turn the GTS on.

- Start the engine.

- Perform the D Position Shift Test inspection in Road Test. [*1]

Click here

.gif)

HINT:

[*1]: Normal judgment procedure.

The normal judgment procedure is used to complete DTC judgment and also used when clearing permanent DTCs.

- Stop the vehicle.

- Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

- Input the DTC: P084000 or P28287F.

- Check the DTC judgment result.

GTS Display

Description

NORMAL

- DTC judgment completed

- System normal

ABNORMAL

- DTC judgment completed

- System abnormal

INCOMPLETE

- DTC judgment not completed

- Perform driving pattern after confirming DTC enabling conditions

N/A

- Unable to perform DTC judgment

- Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

HINT:

- If the judgment result shows NORMAL, the system is normal.

- If the judgment result shows ABNORMAL, the system has a malfunction.

- If the judgment result shows INCOMPLETE or N/A, perform the normal judgment procedure again.

WIRING DIAGRAM

Refer to DTC P084011.

Click here .gif)

CAUTION / NOTICE / HINT

CAUTION:

- Do not perform a stall test if there are any people or objects near the

vehicle.

.png)

- The vehicle could begin moving suddenly, resulting in a serious accident.

- Do not perform a stall test if any wheel chock is out of position.

.png)

- The vehicle could begin moving suddenly, resulting in a serious accident.

- Do not perform the stall test on a slippery or low-friction surface that

could allow the tires to spin.

.png)

- The vehicle could begin moving suddenly, resulting in a serious accident.

NOTICE:

- Perform the universal trip to clear permanent DTCs.

Click here

.gif)

.gif)

- Perform registration and/or initialization when parts related to the continuously

variable transaxle system are replaced.

Click here

.gif)

- Check that no DTCs are stored after performing initialization.

Click here

.gif)

.gif)

HINT:

If any DTCs other than P084000 or P28287F are output, perform troubleshooting for those DTCs first.

PROCEDURE

|

1. |

CHECK DTC OUTPUT (IN ADDITION TO DTC P084000 AND P28287F) |

(a) Enter the following menus:

Powertrain > Transmission > Trouble Codes(b) Read the DTCs using the GTS.

HINT:

- If DTC P084011 or P084015 is output, perform troubleshooting for that DTC first.

- If DTCs P084011 and P084015 are not output but DTC P282812 or P282814 is output, perform troubleshooting for DTC P282812 or P282814 first.

|

Result |

Proceed to |

|---|---|

|

Only DTC P084000 is output |

A |

|

Only DTC P28287F is output |

B |

|

Both DTC P084000 and P28287F are output |

C |

|

DTC P084000 and/or P28287F and P084011 are output |

D |

|

DTC P084000 and/or P28287F and P084015 are output |

E |

|

DTC P084000 and/or P28287F and P282812 output |

F |

|

DTC P084000 and/or P28287F and P282814 output |

G |

|

DTC P084000 and/or P28287F and DTCs other than P084011, P084015, P282812 and P282814 are output |

H |

| B | .gif) |

GO TO STEP 6 |

| C | .gif) |

GO TO STEP 8 |

| D | .gif) |

GO TO DTC CHART (DTC P084011) |

| E | .gif) |

GO TO DTC CHART (DTC P084015) |

| F | .gif) |

GO TO DTC CHART (DTC P282812) |

| G | .gif) |

GO TO DTC CHART (DTC P282814) |

| H | .gif) |

GO TO DTC CHART |

|

|

2. |

READ VALUE USING GTS (BELT CLAMPING FORCE SENSOR) |

CAUTION:

A stall speed test should always be performed with at least 2 people. One person should observe the condition of the wheels and wheel chocks while the other is performing the test.

NOTICE:

- This test must be performed after checking and confirming that the engine is normal.

- Perform this test with the CVT fluid temperature between 50 and 100°C (122 and 212°F).

- Perform this test with the air conditioning off.

- Do not perform the stall speed test for longer than 5 seconds.

- When performing the stall speed test repeatedly, wait for 15 seconds or more between tests.

- Perform this test with the AUTO function (shift-linked function) of the electric parking brake system off.

(a) Warm up the engine.

(b) Fully apply the parking brake and chock all 4 wheels.

HINT:

When the parking brake indicator (red) is illuminated after the electric parking brake switch (electric parking brake switch assembly) has been pulled to the lock side, the maximum amount of braking force is applied if the electric parking brake switch (electric parking brake switch assembly) is pulled to the lock side one more time.

(c) Enter the following menus:

(d) According to the display on the GTS, perform the Active Test.

Powertrain > Transmission > Active Test|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Activate the TC Terminal |

Turn on and off TC and TE1 (CG) connection |

ON or OFF |

|

(e) Enter the following menus:

(f) According to the display on the GTS, read the Data List.

Powertrain > Transmission > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Belt Clamping Force Sensor |

Secondary oil pressure value |

Min.: -64 MPa Max.: 63.998 MPa |

Secondary oil pressure inspection:

|

- |

|

Active Test Display |

|---|

|

Activate the TC Terminal |

|

Data List Display |

|---|

|

Belt Clamping Force Sensor |

|

Result |

Proceed to |

|---|---|

|

Data List value is normal |

A |

|

Data List value is not normal |

B |

| A | .gif) |

CHECK FOR INTERMITTENT PROBLEMS Click here Click here |

|

|

3. |

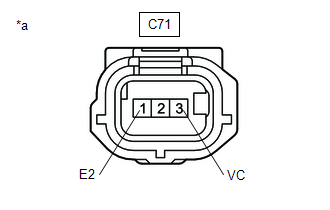

CHECK TCM (VCPT TERMINAL VOLTAGE) |

|

(a) Disconnect the oil pressure sensor connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C71-3 (VC) - C71-1 (E2) |

Ignition switch ON |

4.75 to 5.25 V |

(c) Connect the oil pressure sensor connector.

| NG | .gif) |

GO TO STEP 5 |

|

|

4. |

REPLACE OIL PRESSURE SENSOR |

Click here .gif)

| NEXT | .gif) |

PERFORM INITIALIZATION |

|

5. |

REPLACE TCM |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

|

6. |

READ VALUE USING GTS (BELT CLAMPING FORCE SENSOR) |

CAUTION:

A stall speed test should always be performed with at least 2 people. One person should observe the condition of the wheels and wheel chocks while the other is performing the test.

NOTICE:

- This test must be performed after checking and confirming that the engine is normal.

- Perform this test with the CVT fluid temperature between 50 and 100°C (122 and 212°F).

- Perform this test with the air conditioning off.

- Do not perform the stall speed test for longer than 5 seconds.

- When performing the stall speed test repeatedly, wait for 15 seconds or more between tests.

- Perform this test with the AUTO function (shift-linked function) of the electric parking brake system off.

(a) Warm up the engine.

(b) Fully apply the parking brake and chock all 4 wheels.

HINT:

When the parking brake indicator (red) is illuminated after the electric parking brake switch (electric parking brake switch assembly) has been pulled to the lock side, the maximum amount of braking force is applied if the electric parking brake switch (electric parking brake switch assembly) is pulled to the lock side one more time.

(c) Enter the following menus:

(d) According to the display on the GTS, perform the Active Test.

Powertrain > Transmission > Active Test|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Activate the TC Terminal |

Turn on and off TC and TE1 (CG) connection |

ON or OFF |

|

(e) Enter the following menus:

(f) According to the display on the GTS, read the Data List.

Powertrain > Transmission > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Belt Clamping Force Sensor |

Secondary oil pressure value |

Min.: -64 MPa Max.: 63.998 MPa |

Secondary oil pressure inspection:

|

- |

|

Active Test Display |

|---|

|

Activate the TC Terminal |

|

Data List Display |

|---|

|

Belt Clamping Force Sensor |

|

Result |

Proceed to |

|---|---|

|

Data List value is normal |

A |

|

Data List value is not normal |

B |

| A | .gif) |

CHECK FOR INTERMITTENT PROBLEMS Click here Click here |

|

|

7. |

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

|

8. |

READ VALUE USING GTS (BELT CLAMPING FORCE SENSOR) |

CAUTION:

A stall speed test should always be performed with at least 2 people. One person should observe the condition of the wheels and wheel chocks while the other is performing the test.

NOTICE:

- This test must be performed after checking and confirming that the engine is normal.

- Perform this test with the CVT fluid temperature between 50 and 100°C (122 and 212°F).

- Perform this test with the air conditioning off.

- Do not perform the stall speed test for longer than 5 seconds.

- When performing the stall speed test repeatedly, wait for 15 seconds or more between tests.

- Perform this test with the AUTO function (shift-linked function) of the electric parking brake system off.

(a) Warm up the engine.

(b) Fully apply the parking brake and chock all 4 wheels.

HINT:

When the parking brake indicator (red) is illuminated after the electric parking brake switch (electric parking brake switch assembly) has been pulled to the lock side, the maximum amount of braking force is applied if the electric parking brake switch (electric parking brake switch assembly) is pulled to the lock side one more time.

(c) Enter the following menus:

(d) According to the display on the GTS, perform the Active Test.

Powertrain > Transmission > Active Test|

Tester Display |

Measurement Item |

Control Range |

Diagnostic Note |

|---|---|---|---|

|

Activate the TC Terminal |

Turn on and off TC and TE1 (CG) connection |

ON or OFF |

|

(e) Enter the following menus:

(f) According to the display on the GTS, read the Data List.

Powertrain > Transmission > Data List|

Tester Display |

Measurement Item |

Range |

Normal Condition |

Diagnostic Note |

|---|---|---|---|---|

|

Belt Clamping Force Sensor |

Secondary oil pressure value |

Min.: -64 MPa Max.: 63.998 MPa |

Secondary oil pressure inspection:

|

- |

|

Active Test Display |

|---|

|

Activate the TC Terminal |

|

Data List Display |

|---|

|

Belt Clamping Force Sensor |

|

Result |

Proceed to |

|---|---|

|

Data List value is normal |

A |

|

Data List value is not normal |

B |

| A | .gif) |

CHECK FOR INTERMITTENT PROBLEMS Click here Click here |

|

|

9. |

CHECK TCM (VCPT TERMINAL VOLTAGE) |

|

(a) Disconnect the oil pressure sensor connector. |

|

(b) Measure the voltage according to the value(s) in the table below.

Standard Voltage:

|

Tester Connection |

Condition |

Specified Condition |

|---|---|---|

|

C71-3 (VC) - C71-1 (E2) |

Ignition switch ON |

4.75 to 5.25 V |

(c) Connect the oil pressure sensor connector.

| NG | .gif) |

GO TO STEP 13 |

|

|

10. |

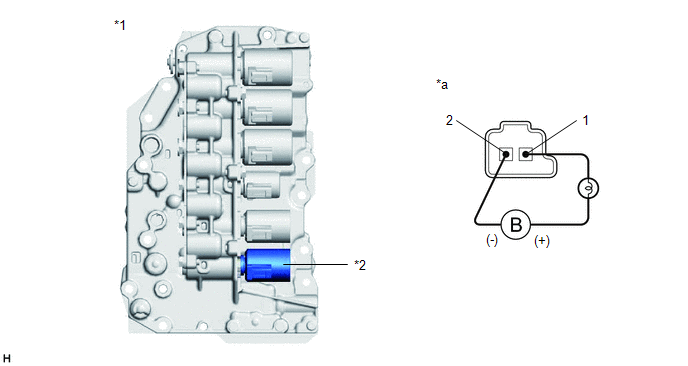

INSPECT TRANSMISSION VALVE BODY ASSEMBLY (SHIFT SOLENOID VALVE SLS) |

(a) Disconnect the transmission wire connector from the shift solenoid valve SLS.

Click here .gif)

|

*1 |

Transmission Valve Body Assembly |

*2 |

Shift Solenoid Valve SLS |

|

*a |

Component without harness connected (Shift Solenoid Valve SLS) |

- |

- |

(b) Connect a positive (+) lead from the auxiliary battery with a 21 W bulb to terminal 1 and a negative (-) lead to terminal 2 of the shift solenoid valve SLS connector. Check that the valve moves and makes an operating sound.

OK:

Valve moves and makes an operating sound.

| NG | .gif) |

GO TO STEP 12 |

|

|

11. |

REPLACE OIL PRESSURE SENSOR |

Click here .gif)

| NEXT | .gif) |

PERFORM INITIALIZATION |

|

12. |

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

|

13. |

REPLACE TCM |

Click here .gif)

.gif)

| NEXT | .gif) |

PERFORM REGISTRATION AND INITIALIZATION for Registration: Click here for Initialization: Click here |

.gif)