Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

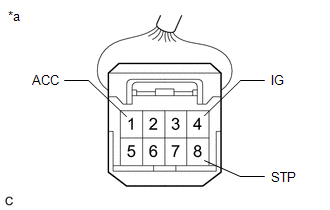

1. INSPECT SHIFT LOCK CONTROL ECU (w/ Smart Key System)

HINT:

If the results of the following inspections are as specified but a malfunction has occurred, replace the shift lock control unit assembly.

(a) Inspect wire harness:

|

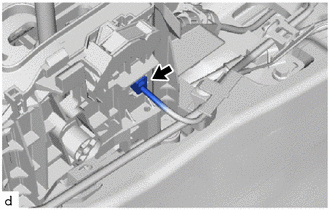

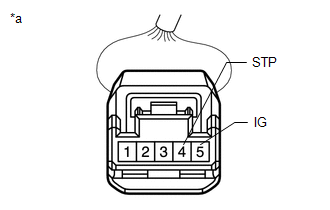

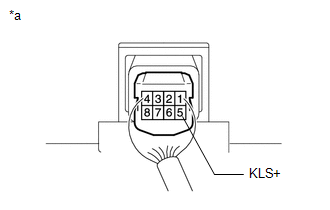

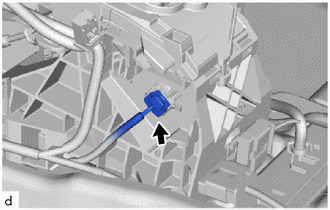

(1) Disconnect the shift lock control ECU connector. |

|

|

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(3) If the result is not as specified, repair or replace the shift lock control ECU wire harness.

|

(4) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(5) If the result is not as specified, repair or replace the shift lock control ECU wire harness.

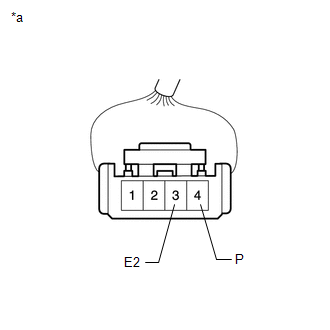

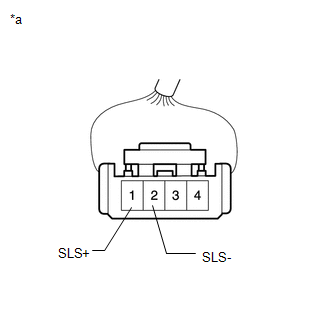

(b) Inspect shift lock solenoid:

|

(1) Disconnect the shift lock solenoid connector. |

|

|

(2) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(3) If the result is not as specified, replace the shift lock control unit assembly.

|

(4) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(5) If the result is not as specified, replace the shift lock control unit assembly.

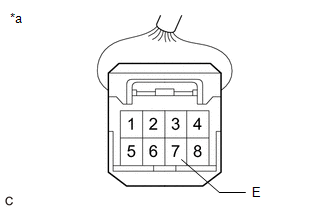

2. INSPECT SHIFT LOCK CONTROL ECU (w/o Smart Key System)

HINT:

If the results of the following inspections are as specified but a malfunction has occurred, replace the shift lock control unit assembly.

(a) Inspect wire harness:

|

(1) Disconnect the shift lock control ECU connector. |

|

|

(2) Measure the voltage according to the value(s) in the table below. Standard Voltage:

|

|

(3) If the result is not as specified, repair or replace the shift lock control ECU wire harness.

|

(4) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(5) If the result is not as specified, repair or replace the shift lock control ECU wire harness.

(b) Inspect key interlock solenoid operation signal:

|

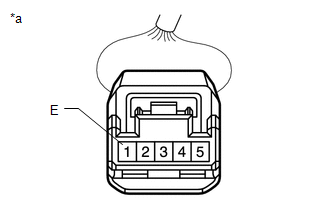

(1) Connect the shift lock control ECU connector. |

|

|

(2) Measure the voltage according to the value(s) in the table below. Standard Resistance:

HINT: Do not disconnect the shift lock control ECU connector. |

|

(3) If the result is not as specified, replace the shift lock control unit assembly.

(c) Inspect shift lock solenoid:

|

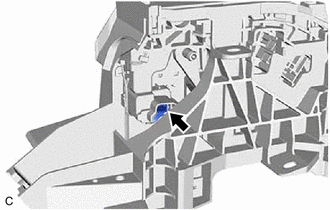

(1) Disconnect the shift lock solenoid connector. |

|

|

(2) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(3) If the result is not as specified, replace the shift lock control unit assembly.

|

(4) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(5) If the result is not as specified, replace the shift lock control unit assembly.

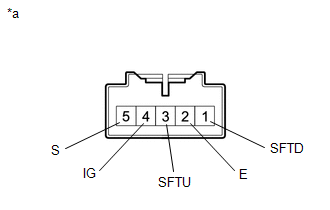

3. INSPECT TRANSMISSION CONTROL SWITCH

|

(a) Disconnect the transmission control switch connector. |

|

|

(b) Measure the resistance according to the value(s) in the table below. Standard Resistance:

|

|

(c) If the result is not as specified, replace the shift lock control unit assembly.