Toyota Corolla Cross: Inspection

INSPECTION

PROCEDURE

1. INSPECT FRONT SEAT ADJUSTER ASSEMBLY

(a) Check the operation of the slide motor.

| (1) Check that the seat cushion moves smoothly when the auxiliary battery is connected to the slide motor connector terminals.

OK: |

Auxiliary Battery Connection |

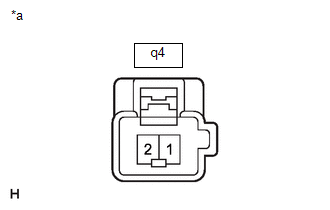

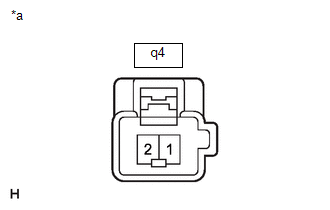

Operational Direction | | Auxiliary battery positive (+) → q4-2

Auxiliary battery negative (-) → q4-1 |

Seat cushion moves forward | |

Auxiliary battery positive (+) → q4-1 Auxiliary battery negative (-) → q4-2 |

Seat cushion moves backward | If the result is not as specified, replace the front seat adjuster assembly. |

|

|

*a | Component without harness connected

(Slide Motor (Front Seat Adjuster Assembly)) | | |

(b) Check the operation of the lifter motor.

| (1) Check that the seat cushion moves smoothly when the auxiliary battery is connected to the lifter motor connector terminals.

OK: |

Auxiliary Battery Connection |

Operational Direction | |

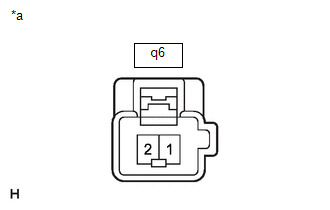

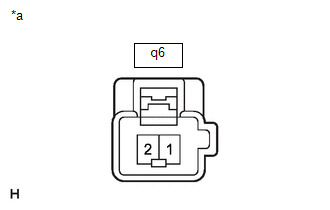

Auxiliary battery positive (+) → q6-1 Auxiliary battery negative (-) → q6-2 |

Seat cushion moves upward | |

Auxiliary battery positive (+) → q6-2 Auxiliary battery negative (-) → q6-1 |

Seat cushion moves downward | If the result is not as specified, replace the front seat adjuster assembly. |

|

|

*a | Component without harness connected

(Lifter Motor (Front Seat Adjuster Assembly)) | | |

(c) Check the operation of the front vertical motor.

| (1) Check that the seat cushion moves smoothly when the auxiliary battery is connected to the front vertical motor connector terminals.

OK: |

Auxiliary Battery Connection |

Operational Direction | |

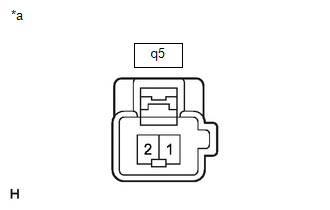

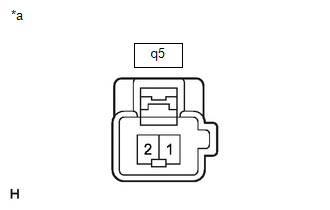

Auxiliary battery positive (+) → q5-1 Auxiliary battery negative (-) → q5-2 |

Seat cushion moves upward | |

Auxiliary battery positive (+) → q5-2 Auxiliary battery negative (-) → q5-1 |

Seat cushion moves downward | If the result is not as specified, replace the front seat adjuster assembly. |

|

|

*a | Component without harness connected

(Front Vertical Motor (Front Seat Adjuster Assembly)) | | |

2. INSPECT FRONT SEATBACK FRAME SUB-ASSEMBLY

(a) Check the operation of the reclining motor.

| (1) Check that the seatback moves smoothly when the auxiliary battery is connected to the reclining motor connector terminals.

OK: |

Auxiliary Battery Connection |

Operational Direction | |

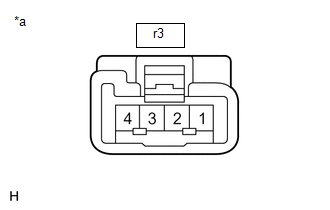

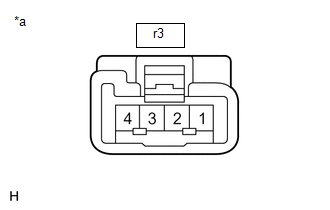

Auxiliary battery positive (+) → r3-1 Auxiliary battery negative (-) → r3-4 |

Seatback moves forward | |

Auxiliary battery positive (+) → r3-4 Auxiliary battery negative (-) → r3-1 |

Seatback moves backward | If the result is not as specified, replace the front seatback frame sub-assembly. |

|

|

*a | Component without harness connected

(Reclining Motor (Front Seatback Frame Sub-assembly)) | | |

READ NEXT:

REASSEMBLY CAUTION / NOTICE / HINT COMPONENTS (REASSEMBLY)

Procedure Part Name Code

1 SEAT TRACK REAR UPPER COVER

72125V -

- -

2 SEAT T

INSTALLATION CAUTION / NOTICE / HINT COMPONENTS (INSTALLATION)

Procedure Part Name Code

1 FRONT SEAT ASSEMBLY

-

- -

2 SEAT TRACK

SEE MORE:

PROBLEM SYMPTOMS TABLE

HINT:

Use the table below to help determine the cause of problem symptoms. If multiple suspected areas are listed, the potential causes of the symptoms are listed in order of probability in the "Suspected Area" column of the table. Check each symptom by checking the susp

TARGET ADJUSTMENT(TRIANGLE TARGET)

CAUTION / NOTICE / HINT

CAUTION:

Radiofrequency radiation exposure information:

This equipment complies with FCC radiation exposure limits set forth

for an uncontrolled environment.

This equipment should be kept with minimum distance of 20 cm (7.87 in